How PIC18F45K80-I/PT CAN/LIN Interfaces Simplify Communication

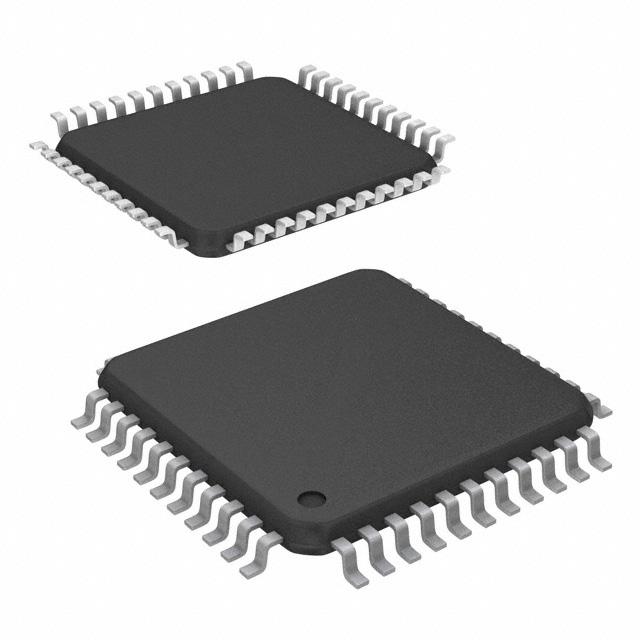

The PIC18F45K80-I/PT microcontroller, equipped with a CAN/LIN communication interface, simplifies and accelerates data sharing within systems.

The CAN Bus is ideal for fast and error-free data transfer, while the LIN Bus offers a cost-effective solution for simpler systems. Together, these interfaces, integrated into the PIC18F45K80-I/PT, address the demands of automotive, industrial, and smart device applications.

The car communication market is projected to grow from $12.86 billion in 2024 to $14.9 billion in 2025, driven by the adoption of CAN and LIN technologies.

The LIN Transceiver Market is expected to reach $2.5 billion by 2033, highlighting its critical role in basic automotive systems.

The PIC18F45K80-I/PT microcontroller with its CAN/LIN communication interface continues to deliver reliable and cost-efficient solutions for modern systems.

Key Takeaways

The PIC18F45K80-I/PT microcontroller makes communication easier with built-in CAN and LIN. It works great for cars and factories.

CAN is great for fast and reliable data sharing in important systems. LIN is cheaper and works well for simpler jobs, making systems better.

Using both CAN and LIN together creates a flexible system. It can handle both hard and easy tasks well.

The microcontroller has features like working in hot or cold places and many ways to connect. This makes it useful in tough environments.

Adding CAN and LIN to your projects can make them work better and cost less. It’s a smart pick for modern systems.

Overview of the PIC18F45K80-I/PT Microcontroller

Key Features and Specifications

The PIC18F45K80-I/PT microcontroller has many features for modern systems. It works well in different applications and ensures reliable performance. Below are its main technical details:

Specification | Details |

|---|---|

Operating Temperature | -40°C to 150°C |

Maximum Clock Frequency | 64 MHz |

Program Memory Size | 32 kB |

RAM Size | 3.6K x 8 |

EEPROM Size | 1K x 8 |

Number of I/O Pins | 35 |

Voltage Supply Range | 4V to 5.5V |

Core Processor | 8-Bit PIC |

Connectivity Options | ECANbus, I²C, LINbus, SPI, UART/USART |

These features make it a great choice for systems needing high performance. It also works well in tough environments.

Communication Capabilities and Supported Protocols

The PIC18F45K80-I/PT microcontroller is excellent at communication. It supports many protocols to make data sharing easier. Its built-in CAN and LIN interfaces help it fit into complex systems. It also supports I²C, SPI, and UART/USART, giving flexibility for different needs.

Standardized protocols improve its communication abilities. For example, the CAN bus is widely used in cars and industries for reliable data sharing. The LIN bus is a cheaper option for simpler systems. These protocols, along with its hardware and software, make it a strong tool for communication.

Importance of Integrated CAN and LIN Interfaces

The CAN and LIN interfaces in the microcontroller make communication easier. CAN bus is great for fast and error-free data sharing. LIN bus is better for simpler and cheaper tasks. Together, they let you adjust your system to fit your needs.

Choosing the right protocol improves performance and saves costs. For example, CAN bus is good for real-time control in cars and factories. LIN bus works well for basic tasks like controlling windows in cars. This dual-interface design makes the microcontroller useful for both advanced and simple systems.

Ongoing improvements in CAN and LIN technologies make them even better. They will stay important for future projects.

Understanding the CAN Interface in the PIC18F45K80-I/PT Microcontroller

Overview of the CAN Protocol and Its Purpose

The Controller Area Network (CAN) protocol helps devices share data quickly. It lets many devices talk to each other without needing a main controller. This protocol is often used in cars, factories, and other systems where reliable communication matters.

CAN makes sure messages are sent without errors. It uses a system where important messages go first. It also checks for mistakes and fixes them, keeping data correct even in noisy places. CAN is great for systems that need fast and dependable data sharing.

Architecture and Functionality of the CAN Module

The CAN module in the PIC18F45K80-I/PT microcontroller makes device communication easier. It is built into the microcontroller, so no extra parts are needed. The module has parts like a message buffer, a CAN controller, and a transceiver.

The message buffer holds messages coming in or going out. The CAN controller handles message priority, fixes errors, and organizes data. The transceiver connects the microcontroller to the CAN bus, allowing data to move back and forth. These parts work together to create a strong communication system.

The CAN module can work in different modes, like normal, listen-only, or loopback. These modes help you test and fix problems without disturbing the main network. This makes the microcontroller useful for many types of projects.

Message Handling and Data Transmission Process

The CAN module in the PIC18F45K80-I/PT microcontroller sends and receives messages efficiently. Each message has an identifier, data, and control bits. The identifier shows how important the message is, and the data contains the information being sent.

Before sending a message, the CAN controller checks if the bus is busy. If it’s free, the message is sent. If many devices try to send messages at once, the system picks the most important one to send first. This stops data from crashing and keeps communication smooth.

When receiving messages, the CAN module only accepts ones with matching identifiers. This helps the microcontroller focus on useful data and avoid overload. It also checks for errors and asks for a resend if needed. This keeps communication reliable.

By using this smart message system, the PIC18F45K80-I/PT microcontroller makes data sharing simple. It ensures your systems work well, even in tough conditions.

Use cases of the CAN interface in embedded systems

The CAN interface is important in many embedded systems. It allows fast and reliable communication, making it useful in different industries. You can see it in cars, factories, and even medical tools. Here are some examples where the CAN interface is very helpful:

Automotive Systems:

In today’s cars, the CAN interface links many control units. These units handle tasks like engine control and braking. For example, when you press the brake, the CAN bus helps the brakes and ABS system work together. This teamwork improves safety and performance.Industrial Automation:

Factories use the CAN interface to connect machines. It helps sensors and controllers work smoothly. For instance, a torque system for motors might use the CAN bus for accurate control. This shows how it works well in tough environments.Medical Devices:

In healthcare, the CAN interface helps devices like ventilators and pumps. These tools need quick and accurate data sharing. For example, a ventilator uses the CAN bus to sync its parts, ensuring patients get the right airflow. This is crucial in emergencies.Robotics:

Robots use the CAN interface to manage their movements. A robotic arm, for example, uses the CAN bus to let motors and sensors talk. This ensures precise actions, which are needed in tasks like surgery or assembly.Smart Agriculture:

On farms, the CAN interface connects machines like tractors. These machines share data about speed and fuel through the CAN bus. This helps farmers save money and work more efficiently.

The CAN interface is flexible and key to modern systems. Whether in cars, factories, or medical tools, it keeps systems running smoothly and reliably.

The PIC18F45K80-I/PT microcontroller includes the CAN bus, making it great for these uses. Its strong design and features make building complex systems easier and faster.

Understanding the LIN Interface in the PIC18F45K80-I/PT Microcontroller

Overview of the LIN Protocol and Its Purpose

The Local Interconnect Network (LIN) protocol is a low-cost way for devices to communicate. It is made for cars and factories where fast data sharing isn’t needed. Think of it as a simpler version of the CAN protocol. It works well for tasks like moving car seats, controlling windows, or turning on lights inside vehicles.

The LIN protocol makes it easy to connect simple systems. It works with the CAN bus to create a system where each part has its job. CAN handles fast and important tasks, while LIN takes care of slower, simpler ones. This setup keeps systems working well without costing too much.

Architecture and Functionality of the LIN Module

The LIN module in the PIC18F45K80-I/PT microcontroller helps devices talk to each other easily. It uses just one wire, which makes it cheaper and less complicated. The module works in a master-slave setup. One master device controls several slave devices.

The LIN module has important parts like a transceiver, data storage, and a protocol manager. The transceiver changes digital signals into electrical ones for sending. Data storage holds messages going in and out. The protocol manager organizes data and keeps everything running by LIN rules.

This design lets the LIN module work well, even in noisy places. It also has sleep and wake-up modes to save power. These features make it a good choice for systems that need simple and affordable communication.

Message Handling and Master-Slave Communication

The LIN protocol uses clear rules to send and receive messages. In a LIN system, the master device starts all communication. It sends a message header that tells slave devices what to do next.

Slave devices answer the master’s header by sending or getting data. This setup keeps communication organized and avoids problems like data crashes. The LIN protocol also checks for mistakes to keep data correct.

This system is great for things like car electronics, such as air conditioning or seat sensors. The master-slave setup ensures these systems work smoothly, even with many devices connected.

The LIN protocol also has sleep and wake-up features. These help save energy by letting devices rest when not in use. They can quickly start again when needed. This is very helpful in cars and smart devices where saving power is important.

Use cases of the LIN interface in embedded systems

The LIN interface is important for systems needing simple, low-cost communication. It works well in cars, factories, and smart devices. Unlike faster protocols like CAN, LIN is used for basic tasks.

Automotive Applications

In cars, the LIN interface helps with non-critical systems. It uses a master-slave setup to keep things running smoothly. Here are some examples:

Window Controls: LIN helps sensors and motors move windows up or down.

Door Locks: It manages locking and unlocking car doors easily and safely.

Rain Sensors: LIN links rain sensors to wipers for automatic activation.

Climate Control: It supports systems that adjust the car’s temperature for comfort.

Below is a table showing more car uses for the LIN interface:

Application Use Case | Description |

|---|---|

Steering Wheel Cluster | Controls for radio, blinkers, and wipers. |

Comfort Cluster | Sensors for sunroof, light, and temperature. |

Powertrain | Speed, position, and pressure sensors. |

Engine Cluster | Cooling fans, small motors, and engine sensors. |

Car Doors | Mirrors, windows, seats, and locks. |

Seats | Sensors for seat position and occupancy. |

Industrial and IoT Applications

The LIN interface is also useful in factories and smart devices. Its simple design makes it great for tasks that don’t need fast communication. For example:

Smart Home Devices: LIN connects lights, HVAC systems, and other home gadgets.

Factory Equipment: It links sensors and controllers in machines for smooth work.

Agricultural Machinery: LIN helps tractors by connecting sensors for speed and fuel.

LIN is perfect for simple, low-speed tasks. It’s a great choice for cars, factories, and IoT projects. It keeps systems affordable and easy to manage.

The PIC18F45K80-I/PT microcontroller includes the LIN protocol, making it ideal for these uses. Its strong design and features help create reliable systems quickly and easily.

Comparing CAN and LIN Interfaces in the PIC18F45K80-I/PT Microcontroller

Key differences in speed, complexity, and cost

CAN and LIN interfaces are different in speed, complexity, and cost. CAN is faster, making it great for important tasks like engine control. LIN is slower, so it’s better for simple jobs like moving windows or turning on lights.

CAN has strong error-checking, which keeps data accurate in noisy places. LIN has basic error-checking, which works fine for easy systems. CAN is more complex and costs more to use. LIN is simpler and cheaper, making it good for low-demand systems.

Here’s a quick comparison:

Metric | CAN | LIN |

|---|---|---|

Communication Speed | High-speed | Low-speed |

Use Case | Critical tasks | Non-critical tasks |

Error Handling | Strong error checking | Basic error checking |

Complementary roles in communication systems

CAN and LIN work well together in systems. CAN handles fast, important tasks, while LIN takes care of smaller, less urgent ones. For example, in a car, CAN might control the engine and brakes. LIN could manage windows and door locks.

This teamwork helps each interface do its job without slowing the system. By using both, you can create a system that handles both big and small tasks efficiently.

Choosing the right interface for specific applications

The right interface depends on what your system needs. If you need fast communication and strong error-checking, choose CAN. It’s great for cars, factories, and robots.

If your system needs to be simple and low-cost, pick LIN. It works well for smart homes, basic car functions, and IoT devices.

The PIC18F45K80-I/PT microcontroller gives you both CAN and LIN options. This lets you pick the best one for your system while keeping costs low.

Practical Uses of CAN and LIN in the PIC18F45K80-I/PT Microcontroller

Car systems and in-vehicle communication

In today’s cars, CAN and LIN interfaces are very important. The CAN interface manages key systems like engine control and braking. It works fast to make sure safety systems respond quickly. For example, when you press the brake, the CAN bus helps the ABS and ESC systems work together smoothly.

The LIN interface is used for simpler tasks. It handles things like moving windows, adjusting seats, or turning on lights. Using a master-slave setup, LIN keeps these systems running without extra cost or complexity. Together, CAN and LIN create a network that handles both big and small tasks in cars.

Factory automation and machine control

In factories, CAN and LIN interfaces improve how machines work together. The CAN interface links sensors, motors, and controllers in real-time. For example, in a robotic assembly line, the CAN bus helps robotic arms and conveyor belts move in sync. Its strong error-checking makes it great for noisy factory environments.

The LIN interface is slower but good for simple jobs. It can control things like adjusting conveyor belt speeds or checking storage temperatures. Its low cost makes it perfect for tasks that don’t need fast communication. By using both interfaces, factories can build efficient and affordable systems.

Smart devices and IoT projects

The CAN/LIN interfaces in the PIC18F45K80-I/PT microcontroller are also great for IoT projects. The CAN interface sends important data, like sensor readings, without delay. For example, in smart traffic systems, the CAN bus helps manage real-time data from sensors to improve traffic flow.

The LIN interface works well for cheaper IoT devices. Its master-slave setup is good for tasks like controlling lights or checking room temperatures in smart homes. CAN’s ability to handle many messages and LIN’s simple timing make them a strong team. Together, they offer a flexible solution for IoT networks.

By using both CAN and LIN, you can build IoT systems that are both powerful and affordable, making them useful for many projects.

The PIC18F45K80-I/PT microcontroller makes data sharing easier in systems. Its built-in CAN and LIN modules handle fast and simple communication. It is designed to work well in many areas, like cars and smart devices.

This microcontroller has useful features and is easy to use. It helps create systems that are both efficient and expandable. Its flexibility makes it a great choice for projects needing smooth communication.

FAQ

1. What makes the PIC18F45K80-I/PT microcontroller special?

The PIC18F45K80-I/PT is unique because it has built-in CAN and LIN interfaces. These features make communication in systems easier. It works well in cars, factories, and smart devices. Its strong design ensures it performs reliably, even in tough conditions.

2. How are CAN and LIN interfaces different?

The CAN interface is fast and handles important tasks like engine control. The LIN interface is slower and cheaper, used for simple jobs like moving windows or turning on lights.

3. Can both CAN and LIN interfaces work together?

Yes, they can. CAN manages big, important tasks, while LIN handles smaller, less urgent ones. Together, they make communication smooth and efficient.

4. Why is the PIC18F45K80-I/PT good for cars?

Its CAN and LIN interfaces are great for car systems. CAN handles safety tasks like brakes, while LIN manages things like seat adjustments. It also works well in extreme temperatures, making it reliable for cars.

5. Is the PIC18F45K80-I/PT easy for beginners?

Yes, it is. Its built-in communication tools mean fewer extra parts are needed. It supports many protocols, making it simple to use in different projects.

Tip: Start with easy LIN tasks before trying the more advanced CAN interface. This helps you learn step by step.

See Also

Leveraging FT2232HQ for Streamlined USB to Serial Links

Enhancing Automation Through PIC16F1824-i/SL Microcontroller Insights

Exploring RS-232 Transceiver Choices for Maximum Efficiency

Exploring 74HC00DR Functionality and Its Essential Uses

Exploring ISO1050DUBR CAN Transceiver Applications in Vehicles