the mainstream SMT45A-682 production process

The mainstream SMT45A-682 production process plays a crucial role in modern manufacturing. You encounter this process in industries that require precise and efficient assembly of electronic components. It involves several stages, each designed to ensure high-quality output. By understanding this process, you gain insight into how manufacturers achieve consistency and reliability in their products. The mainstream SMT45A-682 method stands out for its ability to streamline production while maintaining rigorous standards. This approach not only enhances productivity but also supports innovation in various technological fields.

Step-by-Step Production Process

Preparation Phase

Material Selection

In the mainstream SMT45A-682 production process, you start with material selection. This step is crucial because the quality of materials directly impacts the final product. You need to choose components that meet industry standards and specifications. High-quality materials ensure durability and performance. By selecting the right materials, you lay a strong foundation for the entire production process.

Initial Setup and Calibration

Next, you move to the initial setup and calibration. This phase involves preparing the equipment and machinery for production. You must calibrate machines to ensure precision and accuracy. Proper setup minimizes errors and enhances efficiency. By focusing on this step, you ensure that the production process runs smoothly from the start.

Assembly Phase

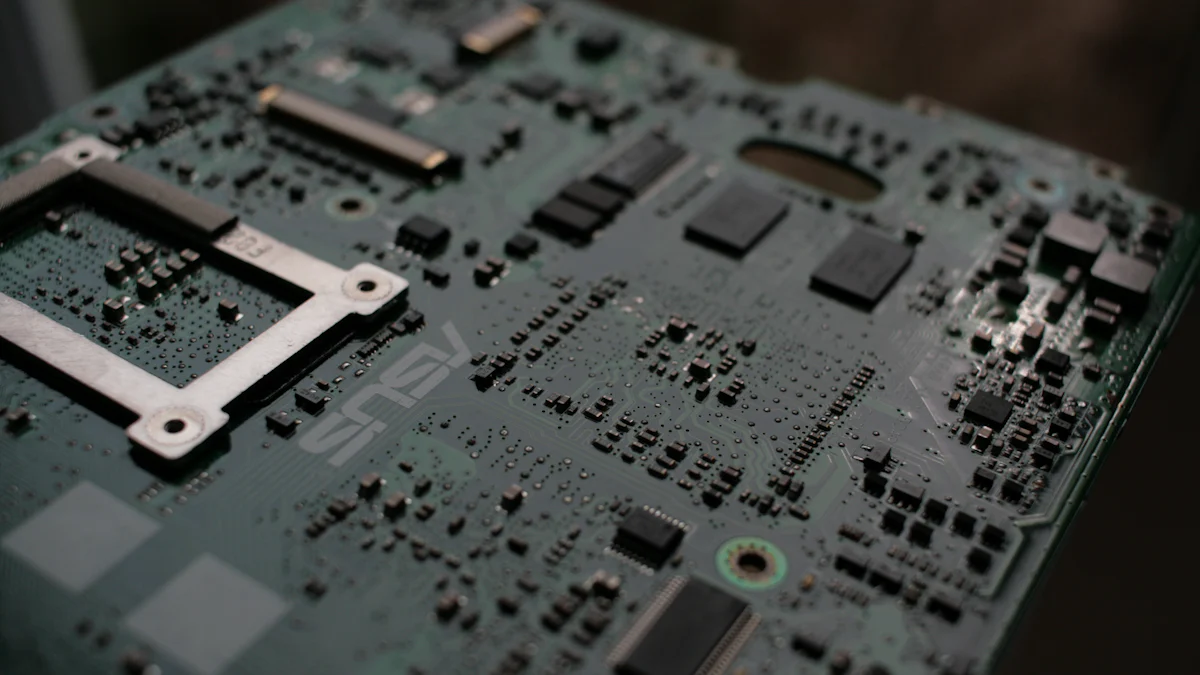

Component Placement

During the assembly phase, you focus on component placement. This step requires precision and attention to detail. You place each component in its designated position on the circuit board. Accurate placement is vital for the functionality of the final product. By mastering this step, you contribute to the overall success of the mainstream SMT45A-682 production process.

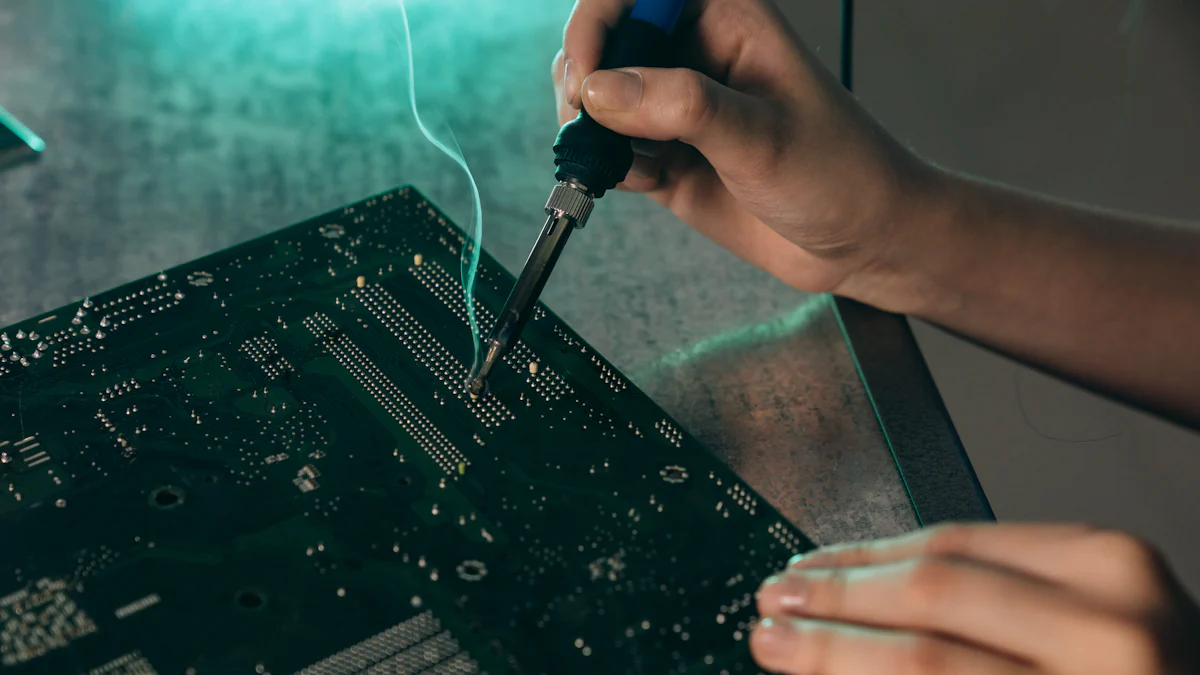

Soldering Techniques

After placing components, you apply soldering techniques. Soldering connects components to the circuit board, ensuring electrical conductivity. You must use the right techniques to avoid defects and ensure reliability. Proper soldering is essential for the integrity of the product. By honing your soldering skills, you enhance the quality of the assembly phase.

Testing Phase

Functional Testing

Once assembly is complete, you proceed to functional testing. This step verifies that the product operates as intended. You test each function to ensure it meets specifications. Functional testing identifies any issues that need correction. By conducting thorough tests, you guarantee the product's performance and reliability.

Stress Testing

Finally, you perform stress testing. This phase evaluates the product's durability under extreme conditions. You simulate various scenarios to test the limits of the product. Stress testing ensures that the product can withstand real-world challenges. By completing this step, you confirm the robustness of the mainstream SMT45A-682 production process.

Technology and Equipment in Mainstream SMT45A-682

In the mainstream SMT45A-682 production process, technology and equipment play a pivotal role. You rely on advanced machinery and sophisticated software to ensure efficiency and precision. This section explores the key technological components that drive the production process.

Advanced Machinery

Automated Assembly Lines

Automated assembly lines form the backbone of the mainstream SMT45A-682 production process. These lines streamline the assembly phase by reducing manual intervention. You benefit from increased speed and accuracy. Automated systems place components with precision, minimizing errors. By using these lines, you enhance productivity and maintain high standards.

Precision Soldering Equipment

Precision soldering equipment is essential for connecting components securely. You use this equipment to apply solder with exactness, ensuring strong electrical connections. The machinery offers consistent results, which is crucial for product reliability. By employing precision soldering tools, you improve the quality of the final product.

Software and Tools

Design and Simulation Software

Design and simulation software are vital in the planning stages. You use these tools to create detailed models of the product. Simulation software allows you to test designs before actual production. This step helps you identify potential issues early, saving time and resources. By leveraging these tools, you optimize the design process and enhance product performance.

Quality Monitoring Systems

Quality monitoring systems ensure that each product meets industry standards. You implement these systems to track production quality in real-time. They provide data on various parameters, helping you detect deviations quickly. By using quality monitoring systems, you maintain consistency and uphold the integrity of the mainstream SMT45A-682 production process.

Quality Control Measures in Mainstream SMT45A-682

Quality control is a cornerstone of the mainstream SMT45A-682 production process. You ensure that each product meets the highest standards by implementing rigorous quality control measures. This section delves into the standards, certifications, and inspection techniques that uphold the integrity of the production process.

Standards and Certifications

Industry Standards Compliance

In the mainstream SMT45A-682 production process, adhering to industry standards is crucial. You must ensure that every component and procedure aligns with established guidelines. These standards guarantee that products are safe, reliable, and efficient. By complying with industry standards, you maintain the trust of consumers and stakeholders.

Certification Processes

Certification processes validate the quality and safety of your products. You undergo thorough evaluations to obtain certifications that demonstrate compliance with industry standards. These certifications serve as a testament to the quality of your production process. By achieving certification, you enhance your reputation and assure customers of your commitment to excellence.

Inspection Techniques

Visual Inspection

Visual inspection is a fundamental technique in quality control. You examine each product visually to identify any defects or irregularities. This step allows you to catch issues early in the production process. By conducting meticulous visual inspections, you ensure that only products meeting high standards proceed to the next stage.

Automated Testing

Automated testing complements visual inspection by providing precise and consistent results. You use advanced technology to test products for functionality and performance. Automated systems can quickly identify defects that might be missed by the human eye. By incorporating automated testing, you enhance the accuracy and efficiency of the quality control process.

Challenges and Considerations in Mainstream SMT45A-682

Common Production Challenges

Component Availability

In the production process, you often face challenges related to component availability. The demand for electronic components can fluctuate, leading to shortages. You must plan ahead and maintain strong relationships with suppliers. By doing so, you ensure a steady supply of necessary parts. This proactive approach helps you avoid delays and keep production on schedule.

Maintaining Consistency

Consistency is key in manufacturing. You need to ensure that each product meets the same high standards. Variations in production can lead to defects and customer dissatisfaction. To maintain consistency, you should implement strict quality control measures. Regular inspections and testing help you identify and correct any deviations. By focusing on consistency, you uphold the reputation of your products.

Environmental and Safety Considerations

Waste Management

Effective waste management is crucial in the production process. You generate waste materials during manufacturing, which need proper disposal. Implementing recycling programs and reducing waste can minimize environmental impact. You should also comply with regulations regarding hazardous waste. By managing waste responsibly, you contribute to a sustainable production process.

Worker Safety Protocols

Worker safety is a top priority in any production environment. You must establish protocols to protect employees from potential hazards. Providing safety training and personal protective equipment is essential. Regular safety audits help you identify risks and improve safety measures. By prioritizing worker safety, you create a secure and productive workplace.

You have explored the key steps in the production process, from material selection to stress testing. Each phase plays a vital role in ensuring high-quality output. Technology and quality control measures enhance efficiency and reliability. You rely on advanced machinery and software to maintain standards. Challenges like component availability and waste management require proactive strategies. By addressing these issues, you ensure a smooth production process. Understanding these elements helps you appreciate the complexity and precision involved in manufacturing.

See Also

Exploring The Current Landscape Of SMT45A-682 Industry

Understanding How The SMT45A-682 Operates Effectively

Top-Selling Models Of The SMT45A-682 Product Line