the mainstream SMT35A-102LF production process

The mainstream SMT35A-102LF production process plays a vital role in modern electronics manufacturing. It focuses on creating reliable and efficient components that meet the demands of advanced technology. You rely on this process to ensure precision and consistency in electronic devices. Manufacturers prioritize this method to maintain high-quality standards while optimizing production efficiency. By adopting this approach, you can achieve superior performance and durability in your electronic products.

Key Takeaways

- Prioritize high-quality raw materials to enhance the durability and performance of electronic components.

- Implement advanced assembly techniques like Surface Mount Technology (SMT) to improve efficiency and reduce production errors.

- Conduct in-line testing during production to identify defects early and maintain high quality throughout the manufacturing process.

- Adopt automation in assembly to increase precision and speed, minimizing human error and ensuring uniformity.

- Focus on waste reduction and energy efficiency to promote sustainability while optimizing production costs.

- Stay informed about emerging trends in technology to leverage the potential of the SMT35A-102LF in future innovations.

- Adhere to industry standards and certifications to build trust and ensure compliance with quality benchmarks.

Key Stages of the Mainstream SMT35A-102LF Production Process

Understanding the key stages of the mainstream SMT35A-102LF production process helps you appreciate how precision and quality come together in electronics manufacturing. Each stage plays a critical role in ensuring the final product meets high standards.

Material preparation and selection

The production process begins with material preparation and selection. You must choose high-quality raw materials to ensure the durability and reliability of the final product. Manufacturers often conduct thorough evaluations to confirm the materials meet specific performance criteria. This step minimizes the risk of defects during production.

Proper handling of materials is equally important. You need to store components in controlled environments to prevent contamination or damage. This ensures that every material used in the mainstream SMT35A-102LF process maintains its integrity before assembly begins.

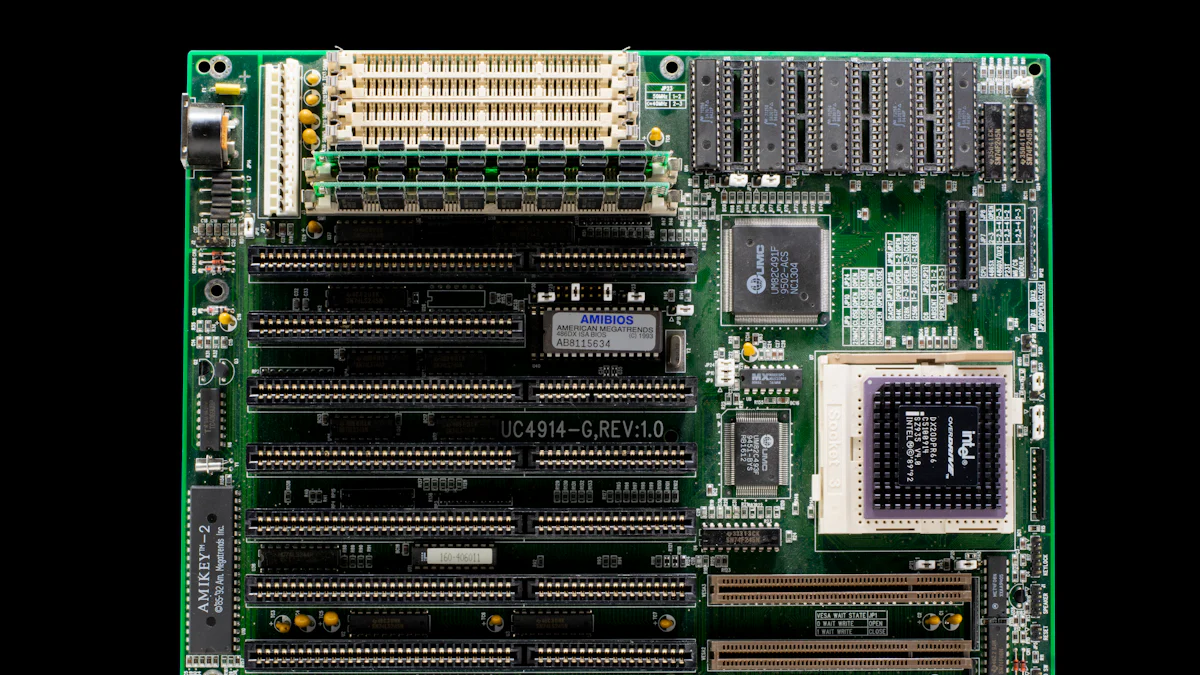

Assembly and component placement

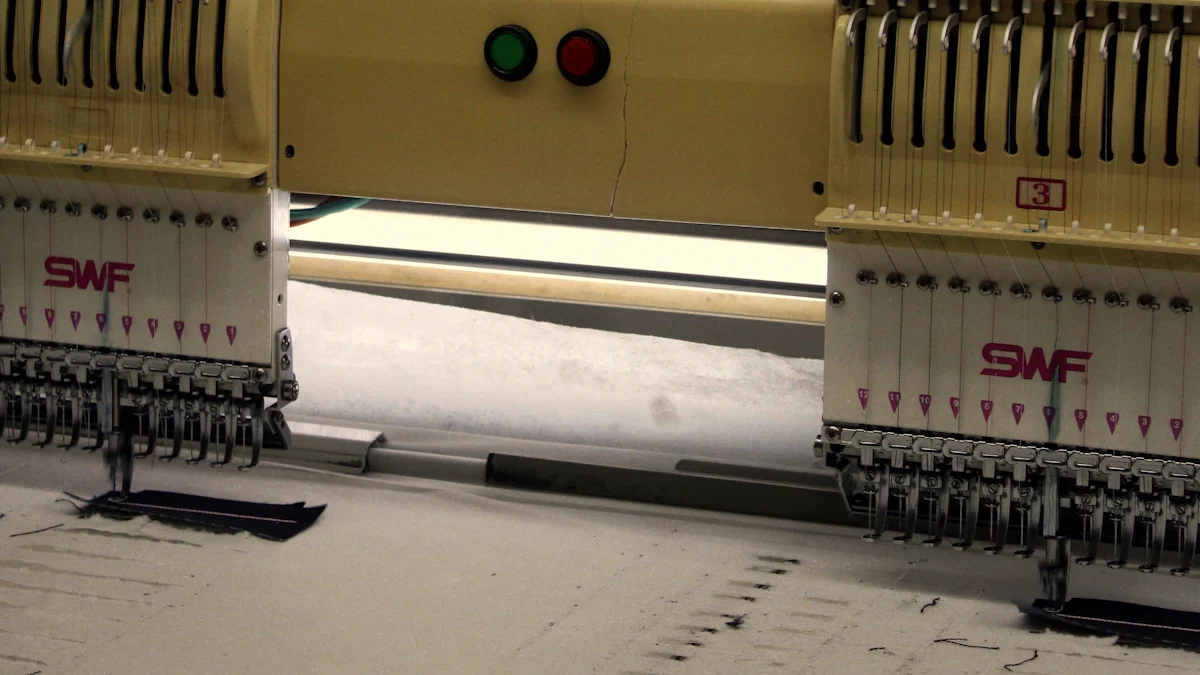

Assembly and component placement form the heart of the production process. You rely on advanced machinery to position components with extreme accuracy. Surface Mount Technology (SMT) plays a significant role here, allowing you to place components directly onto the printed circuit board (PCB). This method enhances efficiency and reduces errors.

Automation further improves precision during this stage. Machines handle repetitive tasks with consistent accuracy, ensuring uniformity across all units. By using automated systems, you can achieve faster production rates without compromising quality.

Testing and quality assurance

Testing and quality assurance ensure the reliability of the final product. During production, you perform in-line testing to identify and address issues immediately. This proactive approach prevents defective units from progressing further in the process.

Post-production testing verifies the product's performance under various conditions. You simulate real-world scenarios to confirm the component's durability and functionality. Adhering to strict quality standards guarantees that the mainstream SMT35A-102LF meets industry requirements and customer expectations.

Material Preparation in the Mainstream SMT35A-102LF Process

Material preparation forms the foundation of the mainstream SMT35A-102LF production process. You must focus on this stage to ensure the final product meets high-quality standards. Proper preparation minimizes errors and enhances the efficiency of subsequent stages.

Selection of high-quality raw materials

You need to prioritize the selection of premium raw materials. High-quality materials directly impact the durability and performance of the final product. Manufacturers often evaluate materials based on their physical and chemical properties. This ensures compatibility with the production process and the intended application.

When choosing materials, you should consider factors like conductivity, thermal resistance, and structural integrity. These characteristics determine how well the materials perform under various conditions. By selecting superior materials, you reduce the risk of defects and improve the reliability of the mainstream SMT35A-102LF components.

Pre-production testing for material integrity

Testing materials before production is essential. You must verify their integrity to avoid issues during manufacturing. Pre-production testing involves assessing the materials for strength, flexibility, and resistance to environmental factors. These tests help identify potential weaknesses that could compromise the final product.

You can use advanced testing methods to ensure accuracy. Techniques like X-ray inspection and thermal analysis provide detailed insights into material properties. By conducting thorough tests, you confirm that the materials meet the required specifications for the mainstream SMT35A-102LF process.

Proper storage and handling protocols

Proper storage and handling of materials are critical to maintaining their quality. You should store materials in controlled environments to prevent contamination or degradation. Factors like temperature, humidity, and exposure to light can affect material properties. Implementing strict storage protocols ensures the materials remain in optimal condition.

Handling materials with care is equally important. You must use appropriate tools and equipment to avoid damage during transportation or assembly. Training your team on proper handling techniques reduces the risk of errors and ensures consistency throughout the production process.

"The quality of a product is only as good as the materials used to create it." This principle underscores the importance of meticulous material preparation in the mainstream SMT35A-102LF process.

Assembly Techniques in the Mainstream SMT35A-102LF Process

Assembly techniques play a crucial role in the mainstream SMT35A-102LF production process. These methods ensure precision and efficiency, which are essential for creating high-quality electronic components. By understanding these techniques, you can appreciate how advanced technology contributes to reliable manufacturing.

Surface Mount Technology (SMT) and its role

Surface Mount Technology (SMT) revolutionizes the assembly process. It allows you to place components directly onto the surface of a printed circuit board (PCB). This method eliminates the need for traditional through-hole mounting, which requires drilling holes into the PCB. SMT enhances efficiency by reducing production time and material usage.

You benefit from SMT's ability to handle smaller components. Modern electronics demand compact designs, and SMT meets this requirement with ease. The technology also improves electrical performance by minimizing signal loss and interference. By adopting SMT, you achieve precise component placement and superior functionality in your products.

Automation in assembly for precision

Automation transforms the assembly stage into a highly accurate and efficient process. Machines equipped with advanced sensors and software handle tasks like component placement and alignment. These systems work faster and more consistently than manual methods, ensuring uniformity across all units.

You can rely on automation to reduce human error. Machines follow programmed instructions with precision, eliminating inconsistencies that may arise from manual handling. Automation also increases production speed, allowing you to meet high demand without compromising quality. By integrating automated systems, you streamline the assembly process and enhance overall productivity.

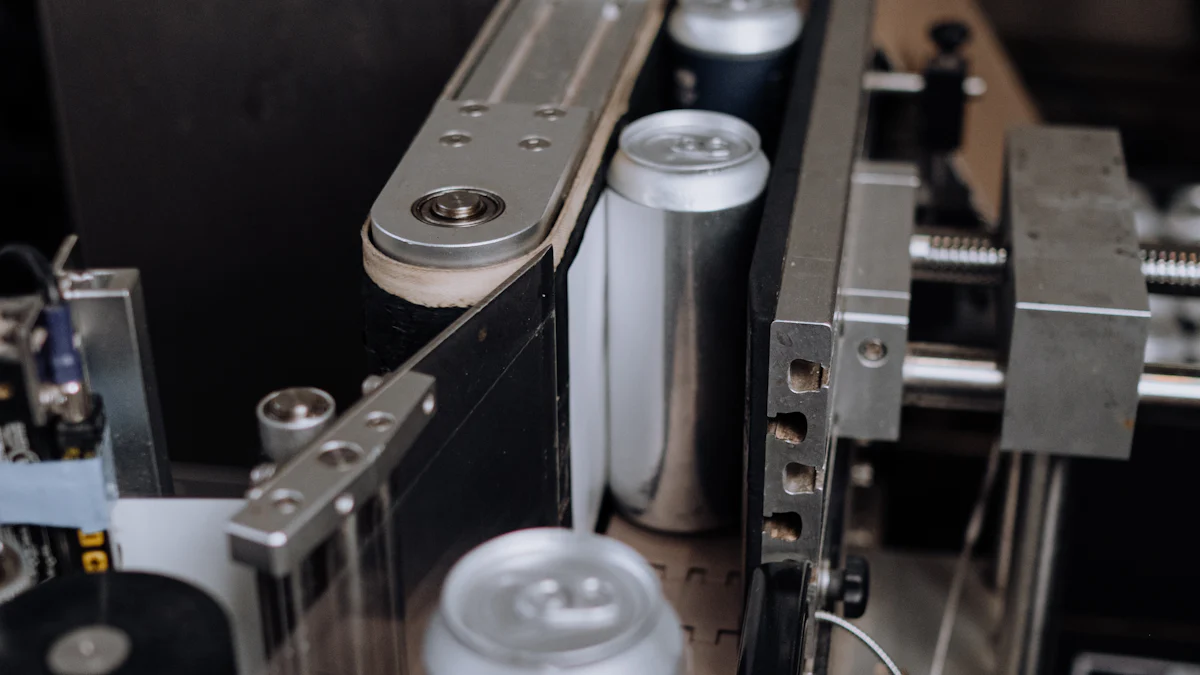

Soldering methods and their importance

Soldering secures components to the PCB, making it a critical step in the assembly process. You must choose the right soldering method to ensure strong and reliable connections. Common techniques include reflow soldering and wave soldering, each suited for specific applications.

Reflow soldering uses heat to melt solder paste, bonding components to the PCB. This method works well with SMT and provides precise control over temperature and timing. Wave soldering, on the other hand, involves passing the PCB over a wave of molten solder. It is ideal for through-hole components and mixed-technology assemblies.

Proper soldering prevents issues like weak joints or electrical failures. You should monitor the process closely to maintain consistent quality. By mastering soldering techniques, you ensure the durability and performance of the mainstream SMT35A-102LF components.

"Precision in assembly defines the reliability of the final product." This principle highlights the importance of advanced techniques in the mainstream SMT35A-102LF production process.

Quality Control in the Mainstream SMT35A-102LF Process

Quality control ensures that every component produced meets the highest standards. You must focus on this stage to guarantee the reliability and performance of the mainstream SMT35A-102LF. By implementing rigorous testing and adhering to industry benchmarks, you can deliver products that consistently satisfy customer expectations.

In-line testing during production

In-line testing plays a crucial role in identifying issues early in the production process. You perform these tests while manufacturing is still underway. This proactive approach allows you to detect and resolve defects before they affect the final product.

You can use advanced tools like automated optical inspection (AOI) systems to monitor the assembly process. These systems scan for misaligned components, soldering defects, or other irregularities. By addressing problems immediately, you reduce waste and improve overall efficiency. In-line testing ensures that each unit progresses through production with minimal errors.

Post-production testing for reliability

Post-production testing verifies the functionality and durability of the finished product. You simulate real-world conditions to evaluate how the component performs under stress. This step ensures that the mainstream SMT35A-102LF can withstand various environmental factors and operational demands.

Common tests include thermal cycling, vibration analysis, and electrical performance checks. These assessments help you confirm that the product meets design specifications and industry requirements. By conducting thorough post-production testing, you enhance customer confidence in the reliability of your components.

Adherence to industry standards and certifications

Adhering to industry standards and certifications demonstrates your commitment to quality. You must follow established guidelines to ensure that your products meet regulatory and safety requirements. Compliance with these standards also helps you maintain consistency across all production batches.

Certifications like ISO 9001 or IPC standards validate your manufacturing processes. They provide assurance to customers that your components meet global benchmarks for quality and reliability. By prioritizing adherence to these standards, you strengthen your reputation and build trust in your products.

"Quality control is not an option; it is a necessity." This principle highlights the importance of maintaining strict quality measures throughout the mainstream SMT35A-102LF production process.

Efficiency and Sustainability in the Mainstream SMT35A-102LF Process

Efficiency and sustainability have become essential in modern manufacturing. By focusing on these aspects, you can optimize production while minimizing environmental impact. The mainstream SMT35A-102LF process incorporates advanced practices to achieve these goals.

Advanced manufacturing technologies

You can rely on advanced manufacturing technologies to enhance efficiency. These technologies include automated systems, robotics, and precision tools. They streamline operations and reduce the likelihood of errors. Machines equipped with artificial intelligence (AI) can analyze data in real time, helping you make informed decisions during production.

Using these technologies allows you to maintain consistency across all units. Automated systems handle repetitive tasks with speed and accuracy. This reduces manual intervention and ensures uniform quality. By adopting advanced tools, you can meet high production demands without sacrificing precision.

Streamlined workflows for reduced production time

Streamlined workflows play a critical role in reducing production time. You can organize tasks logically to eliminate unnecessary steps. This approach minimizes delays and improves overall productivity. Clear communication among team members ensures that everyone understands their responsibilities.

You should also focus on optimizing equipment usage. Scheduling regular maintenance prevents unexpected breakdowns, keeping the production line running smoothly. Efficient workflows allow you to complete projects faster, enabling you to meet tight deadlines. By prioritizing organization, you can achieve faster turnaround times without compromising quality.

Waste reduction and environmental considerations

Reducing waste is vital for sustainability. You can implement practices that minimize material waste during production. For example, precise cutting techniques ensure that raw materials are used efficiently. Recycling leftover materials further reduces waste and supports environmental goals.

Energy efficiency is another important factor. You can use energy-saving equipment to lower power consumption. Monitoring energy usage helps you identify areas for improvement. Sustainable practices not only benefit the environment but also reduce operational costs. By focusing on waste reduction, you contribute to a greener future while maintaining profitability.

"Sustainability is not just a choice; it is a responsibility." This principle emphasizes the importance of integrating eco-friendly practices into the mainstream SMT35A-102LF process.

Applications of the Mainstream SMT35A-102LF

The mainstream SMT35A-102LF plays a pivotal role in various industries and electronic applications. Understanding its applications helps you appreciate its versatility and potential for innovation.

Key industries utilizing the component

You will find the mainstream SMT35A-102LF widely used across multiple industries. The telecommunications sector relies on it for creating reliable and efficient communication devices. Its precision and durability make it ideal for high-performance equipment like routers, modems, and signal processors.

In the automotive industry, this component supports advanced systems such as navigation units, sensors, and control modules. These systems demand components that can withstand harsh conditions while maintaining consistent performance. The mainstream SMT35A-102LF meets these requirements effectively.

The medical field also benefits from this component. It powers diagnostic devices, monitoring systems, and other critical equipment. Its reliability ensures accurate results and uninterrupted operation, which are essential in healthcare settings. By using this component, industries achieve higher efficiency and dependability in their operations.

Benefits in various electronic applications

The mainstream SMT35A-102LF enhances the functionality of numerous electronic applications. Its compact design allows you to create smaller, more efficient devices. This feature is crucial for modern electronics, where space-saving designs are a priority.

You can rely on this component for improved energy efficiency. It minimizes power consumption, making it suitable for battery-operated devices like smartphones, tablets, and wearables. This efficiency extends the lifespan of these devices, providing added value to users.

Its robust construction ensures long-term reliability. You can trust it to perform consistently under varying conditions, reducing the need for frequent replacements. This durability makes it a cost-effective choice for manufacturers and end-users alike. By integrating this component, you enhance the overall quality and performance of your electronic products.

Emerging trends and future potential

Emerging trends highlight the growing importance of the mainstream SMT35A-102LF in cutting-edge technologies. The rise of the Internet of Things (IoT) creates new opportunities for this component. You can use it to develop smart devices that communicate seamlessly within connected ecosystems.

Advancements in artificial intelligence (AI) and machine learning also drive demand for this component. It supports the development of intelligent systems that process data efficiently and accurately. These systems include autonomous vehicles, smart home devices, and industrial automation tools.

Future innovations may further expand its applications. As technology evolves, you can expect this component to play a key role in next-generation electronics. Its adaptability and reliability position it as a cornerstone of future advancements. By staying informed about these trends, you can leverage its potential to remain competitive in the ever-changing tech landscape.

"Innovation thrives on reliable components." This principle underscores the significance of the mainstream SMT35A-102LF in shaping the future of electronics.

You have explored the key stages of the mainstream SMT35A-102LF production process, from material preparation to assembly and quality control. Each stage emphasizes precision and efficiency, ensuring reliable components for modern electronics. Quality control remains vital in maintaining high standards and meeting industry expectations.

This component plays a crucial role in advancing technology across industries. Its reliability and adaptability make it indispensable in today’s devices. Looking ahead, innovations in production processes will unlock new possibilities, enabling you to create even more efficient and sustainable solutions for the future of electronics.

See Also

Exploring The Key Features Of SMT35A-102LF

Understanding The Unique Standards Of SMT35A-102LF

The Importance Of SMT35A-102LF In Medical Equipment