Discover the Fascinating Mainstream Production Process Behind J3L-IF10-FB

The J3L-IF10-FB production process stands as a remarkable achievement in modern manufacturing. It transforms raw materials into high-quality products with precision and efficiency. This process holds immense significance due to its ability to meet the growing demands of industries while maintaining consistent quality. You encounter its impact daily, whether in electronics, automotive, or other sectors.

Its adoption as a mainstream production process reflects its reliability and scalability. What makes it fascinating is how it combines advanced technology with innovative methods to revolutionize manufacturing standards.

Key Takeaways

- The J3L-IF10-FB production process combines advanced technology and innovative methods to deliver high-quality products efficiently.

- This process enhances productivity and reduces costs, making it essential for industries like electronics and automotive.

- Sustainability is a core focus, with practices such as recycling and energy-efficient machinery minimizing environmental impact.

- Automation and AI integration streamline operations, ensuring consistent quality and faster production times.

- The versatility of the J3L-IF10-FB process allows it to adapt to various materials and product types, making it widely applicable across industries.

- Rigorous quality control and testing ensure that every product meets high standards, building consumer trust.

- Future advancements in technology promise to further enhance the efficiency and sustainability of the J3L-IF10-FB production process.

What Is the J3L-IF10-FB Production Process?

Overview of J3L-IF10-FB

The J3L-IF10-FB production process represents a cutting-edge approach to manufacturing. It focuses on transforming raw materials into finished products with unmatched precision and efficiency. You can think of it as a system that combines advanced technology with streamlined workflows to deliver consistent results. This process has become a cornerstone in industries like electronics and automotive, where high-quality output is essential.

At its core, the J3L-IF10-FB process integrates innovative techniques to optimize every stage of production. It ensures minimal waste, faster turnaround times, and superior product quality. By leveraging automation and data-driven insights, this process sets a new standard for modern manufacturing.

Importance of the Production Process in Industry

The J3L-IF10-FB production process plays a vital role in meeting the demands of today’s fast-paced industries. You rely on products created through this process in your daily life, from smartphones to vehicles. Its ability to deliver consistent quality makes it indispensable for businesses aiming to maintain their competitive edge.

Industries benefit from this process in several ways:

- Enhanced Productivity: The process reduces delays and maximizes output.

- Cost Savings: Efficient resource utilization lowers production costs.

- Reliability: Consistent results build trust among consumers and businesses.

This production process also supports innovation. It allows manufacturers to experiment with new designs and materials without compromising efficiency. As industries evolve, the J3L-IF10-FB process adapts to meet new challenges.

Why It Is Considered a Mainstream Production Process

The J3L-IF10-FB production process has earned its place as a mainstream production process due to its widespread adoption and proven effectiveness. You see its impact across multiple sectors, from consumer electronics to heavy machinery. Its scalability makes it suitable for both small-scale operations and large industrial setups.

Several factors contribute to its mainstream status:

- High Efficiency: The process minimizes downtime and maximizes throughput.

- Versatility: It accommodates a wide range of materials and product types.

- Sustainability: Eco-friendly practices make it a responsible choice for modern manufacturers.

By addressing the needs of diverse industries, the J3L-IF10-FB process has become a benchmark for excellence in manufacturing. Its ability to balance efficiency, quality, and sustainability ensures its relevance in the years to come.

Key Steps in the J3L-IF10-FB Production Process

Step 1: Sourcing and Preparing Raw Materials

The production process begins with sourcing high-quality raw materials. You must ensure that these materials meet strict standards to guarantee the final product's quality. Manufacturers often collaborate with trusted suppliers to secure reliable resources. This step lays the foundation for the entire process.

Once sourced, the raw materials undergo preparation. You might see processes like cleaning, sorting, or pre-treating materials to make them suitable for the next stages. For example, metals may require cutting or shaping, while other materials might need chemical treatments. Proper preparation ensures smooth transitions into the initial processing phase.

Step 2: Initial Processing and Material Refinement

In this step, the raw materials transform into refined components. You will notice that this phase focuses on enhancing the materials' properties to meet production requirements. Techniques like melting, molding, or machining are common here. Each method depends on the type of material and the product specifications.

For instance, metals might go through heat treatment to improve durability. Plastics could undergo extrusion to achieve the desired shape. These processes ensure that the materials are ready for assembly. Precision plays a critical role here, as even minor errors can affect the final product's quality.

Step 3: Core Manufacturing and Assembly

The core manufacturing stage is where the magic happens. You will see the refined materials come together to form the final product. Advanced machinery and skilled technicians work in harmony to assemble components with precision. This step often involves welding, fastening, or integrating electronic parts.

Automation plays a significant role in this phase. Robots and automated systems handle repetitive tasks, ensuring consistency and speed. You might also notice quality checks embedded within the assembly line. These checks catch defects early, preventing costly errors later.

The assembly process concludes with the creation of a fully functional product. At this point, the product is ready for testing and validation, which ensures it meets industry standards.

Step 4: Quality Control, Testing, and Validation

Quality control ensures that the final product meets the highest standards. You will find this step critical in identifying and eliminating defects. Manufacturers use a combination of manual inspections and automated systems to maintain precision. Every product undergoes rigorous testing to confirm its functionality and durability.

Testing involves subjecting the product to real-world conditions. For example, electronic components might face temperature variations or stress tests. These tests verify that the product performs as expected under different scenarios. You can trust the reliability of products because of these thorough evaluations.

Validation follows testing. This process ensures that the product complies with industry regulations and customer requirements. Manufacturers document every step to maintain transparency. By the end of this phase, you have a product that is ready for the market, free from flaws, and built to last.

Step 5: Packaging, Labeling, and Distribution

Packaging protects the product during transportation and storage. You will notice that manufacturers use materials designed to prevent damage. For instance, fragile items might come with foam padding or bubble wrap. The packaging also reflects the brand’s identity, making it visually appealing to customers.

Labeling provides essential information about the product. You can find details like usage instructions, safety warnings, and compliance certifications. Clear and accurate labeling ensures that customers understand how to use the product correctly. It also builds trust by showcasing the manufacturer’s commitment to quality.

Distribution marks the final step. Products move from factories to warehouses, retailers, or directly to customers. Efficient logistics systems ensure timely delivery. You benefit from this streamlined process because it reduces delays and ensures that products reach you in perfect condition.

Technologies and Methods Used in the Process

Advanced Machinery and Automation Systems

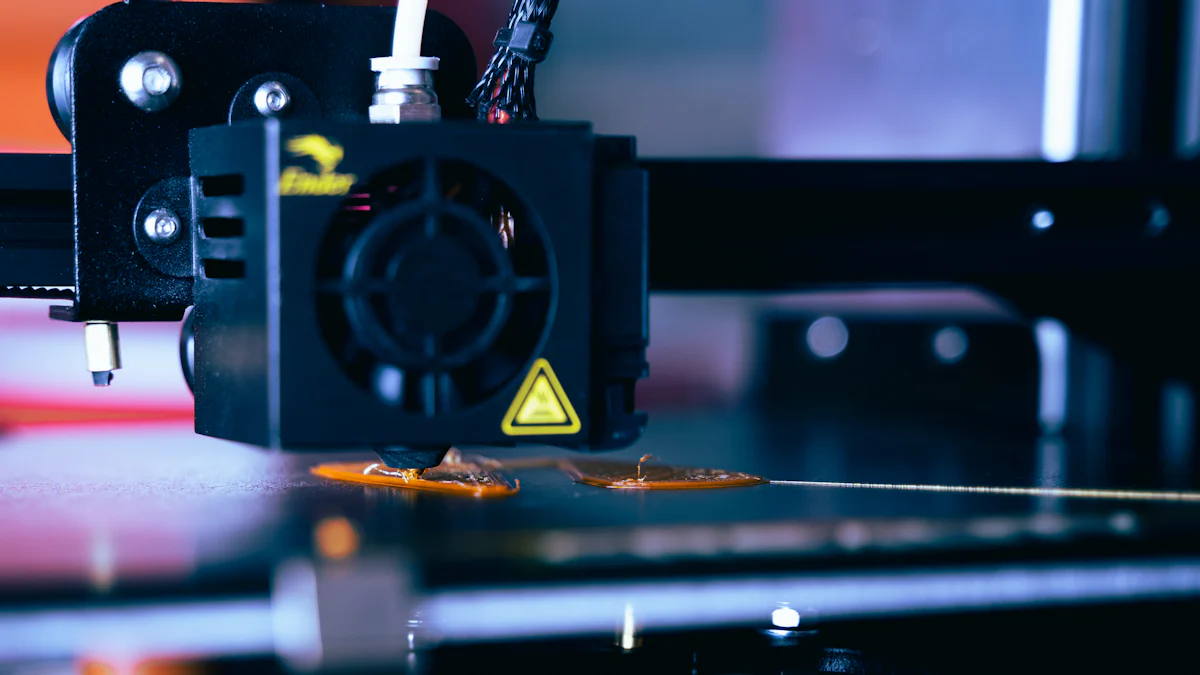

You will find advanced machinery at the heart of the J3L-IF10-FB production process. These machines perform tasks with unmatched speed and precision. Manufacturers rely on equipment like CNC machines, robotic arms, and 3D printers to handle complex operations. Each machine focuses on specific tasks, ensuring every step of production meets high standards.

Automation systems streamline repetitive tasks. Robots assemble components, move materials, and monitor production lines. This reduces human error and increases efficiency. You benefit from products made with consistent quality because of these systems. Automation also allows manufacturers to scale production quickly, meeting growing demands without compromising standards.

"Automation is not just a tool; it’s a necessity for modern manufacturing," says industry expert Dr. Alan Greene.

The integration of advanced machinery ensures that every product is crafted with care and precision. You can trust the reliability of items produced through this process.

Integration of AI and Data Analytics for Optimization

Artificial intelligence (AI) plays a transformative role in the J3L-IF10-FB production process. AI systems analyze vast amounts of data to identify patterns and optimize workflows. You might not see it directly, but AI ensures that every stage of production operates at peak efficiency.

For example, predictive analytics helps manufacturers anticipate equipment failures. This reduces downtime and prevents costly delays. Machine learning algorithms adjust production parameters in real time, ensuring consistent quality. You benefit from faster production times and lower costs because of these innovations.

Data analytics also enhances decision-making. Manufacturers use insights from data to improve processes, reduce waste, and meet customer demands. By leveraging AI and analytics, the J3L-IF10-FB process stays ahead of industry trends.

Adoption of Sustainable and Eco-Friendly Practices

Sustainability takes center stage in the J3L-IF10-FB production process. Manufacturers adopt eco-friendly practices to minimize environmental impact. You can feel good knowing that these efforts contribute to a healthier planet.

Recycling plays a key role. Many manufacturers reuse materials to reduce waste. Energy-efficient machinery lowers power consumption, cutting down on carbon emissions. Water-saving techniques ensure that resources are used responsibly.

"Sustainability is not an option; it’s a responsibility," emphasizes environmental advocate Sarah Collins.

You will also notice the use of biodegradable packaging in many products. This reduces plastic waste and promotes eco-conscious consumerism. By prioritizing sustainability, the J3L-IF10-FB process sets an example for other industries to follow.

These technologies and methods ensure that the J3L-IF10-FB production process remains innovative, efficient, and environmentally responsible. You benefit from high-quality products while supporting practices that protect the planet.

Why Is the J3L-IF10-FB Production Process Mainstream?

High Efficiency and Cost-Effectiveness

The J3L-IF10-FB production process achieves remarkable efficiency by streamlining every stage of manufacturing. You benefit from faster production times because manufacturers use advanced machinery and automation to eliminate delays. Each step operates with precision, ensuring minimal waste and maximum output. This efficiency allows businesses to meet high demand without compromising quality.

Cost-effectiveness stands as another key advantage. By optimizing resource usage, manufacturers reduce expenses on materials and energy. Automation further lowers costs by minimizing labor-intensive tasks. You enjoy affordable products because this process keeps production expenses under control. The balance between efficiency and cost makes it a preferred choice for industries worldwide.

Extensive Adoption Across Multiple Industries

The versatility of the J3L-IF10-FB production process has led to its adoption across various industries. You encounter its results in electronics, automotive, healthcare, and even consumer goods. Its ability to handle diverse materials and product types makes it suitable for a wide range of applications. For example, it produces everything from smartphones to medical devices with consistent quality.

Industries value this process because it adapts to their unique needs. Whether creating small-scale prototypes or large-scale products, the process delivers reliable results. You rely on these products daily, showcasing the widespread impact of this mainstream production process. Its extensive adoption highlights its importance in modern manufacturing.

Proven Reliability and Scalability in Production

Reliability defines the J3L-IF10-FB production process. You can trust the products made through this method because they undergo rigorous quality checks. Manufacturers ensure that every item meets strict standards, reducing the risk of defects. This reliability builds confidence among businesses and consumers alike.

Scalability further enhances its appeal. The process adjusts to different production volumes, making it ideal for both startups and established companies. You benefit from consistent product availability because manufacturers can scale operations quickly. This flexibility ensures that the process remains relevant as industries grow and evolve.

The combination of efficiency, versatility, and reliability cements the J3L-IF10-FB production process as a mainstream production process. Its ability to meet the demands of diverse industries while maintaining high standards ensures its continued dominance in manufacturing.

What Makes the Process Fascinating?

Unique Innovations and Breakthroughs in the Process

The J3L-IF10-FB production process stands out because of its unique innovations. You will notice how it incorporates groundbreaking techniques that redefine manufacturing. For example, the integration of real-time monitoring systems allows manufacturers to detect and resolve issues instantly. This ensures that every product meets the highest standards without delays.

Another fascinating aspect lies in its use of modular assembly lines. These lines adapt to different product designs with minimal adjustments. You benefit from this flexibility because it enables faster production cycles and customized solutions. The process also leverages advanced materials, such as lightweight composites, to enhance product performance while reducing costs.

"Innovation drives progress, and the J3L-IF10-FB process exemplifies this principle," says Dr. Emily Carter, a leading expert in manufacturing technologies.

These breakthroughs make the process not only efficient but also a model for future advancements in the industry.

Transformative Impact on Industries Like Electronics and Automotive

The J3L-IF10-FB production process has revolutionized industries like electronics and automotive. You can see its influence in the devices and vehicles you use daily. In electronics, this process enables the creation of compact, high-performance components. Smartphones, laptops, and wearables owe their reliability and sleek designs to this method.

In the automotive sector, the process supports the production of lightweight yet durable parts. This improves fuel efficiency and vehicle safety. Electric vehicles, in particular, benefit from the precision and scalability of this mainstream production process. Battery components, sensors, and other critical parts achieve consistent quality through this method.

The transformative impact extends beyond products. You also experience faster innovation cycles because manufacturers can experiment with new designs and technologies. This adaptability ensures that industries remain competitive and responsive to market demands.

Future Potential for Technological Advancements

The future of the J3L-IF10-FB production process holds immense potential. You can expect even greater integration of emerging technologies like artificial intelligence and machine learning. These tools will further optimize workflows, reduce waste, and enhance product quality. Predictive maintenance, powered by AI, will minimize downtime and improve efficiency.

Sustainability will also take center stage. You will likely see increased use of renewable energy sources and biodegradable materials in the process. These advancements align with global efforts to reduce environmental impact. Manufacturers will adopt circular economy practices, ensuring that resources are reused and recycled effectively.

The process may also expand into new industries, such as biotechnology and aerospace. You could witness the creation of innovative products, from medical implants to advanced spacecraft components. The J3L-IF10-FB production process will continue to evolve, shaping the future of manufacturing and delivering benefits to you and society as a whole.

Challenges and Opportunities in the J3L-IF10-FB Production Process

Current Limitations and Bottlenecks in the Process

You may notice that even the most advanced production processes face challenges. The J3L-IF10-FB production process is no exception. One major limitation lies in the dependency on high-quality raw materials. When suppliers fail to meet strict standards, the entire production cycle suffers. This creates delays and increases costs.

Another bottleneck involves the integration of new technologies. While automation and AI improve efficiency, they require significant investment and expertise. Smaller manufacturers often struggle to adopt these advancements. You might also see issues with equipment maintenance. Machines operating at high speeds demand regular upkeep, and unexpected breakdowns disrupt production schedules.

Scalability presents another challenge. As demand grows, manufacturers must expand operations without compromising quality. This requires careful planning and resource allocation. You can imagine how difficult it becomes to maintain consistency across larger production volumes.

Opportunities for Enhancing Efficiency and Sustainability

Despite these challenges, the J3L-IF10-FB process offers numerous opportunities for improvement. Manufacturers can enhance efficiency by adopting predictive maintenance systems. These systems use real-time data to identify potential issues before they escalate. You benefit from faster production cycles and fewer delays.

Sustainability also presents a promising avenue. Recycling materials and reducing waste can lower costs while protecting the environment. For example, manufacturers could implement closed-loop systems to reuse resources. Energy-efficient machinery further reduces carbon emissions. You might notice more products featuring biodegradable packaging as companies embrace eco-friendly practices.

Collaboration between industries creates additional opportunities. By sharing knowledge and resources, manufacturers can overcome limitations. For instance, partnerships with technology firms enable the integration of cutting-edge tools. You will see these advancements reflected in higher-quality products and more sustainable practices.

The Role of Emerging Technologies in Overcoming Challenges

Emerging technologies play a critical role in addressing the challenges of the J3L-IF10-FB production process. Artificial intelligence (AI) optimizes workflows by analyzing vast amounts of data. You might not see it directly, but AI ensures that every stage operates at peak efficiency. Machine learning algorithms adjust parameters in real time, reducing errors and waste.

Blockchain technology enhances transparency. It allows manufacturers to track materials and processes with precision. You gain confidence in the quality and authenticity of products. Blockchain also improves supply chain management, ensuring timely delivery of raw materials.

Historical breakthroughs remind us of the transformative power of innovation. For example, the production of the first Buffalo Nickel in 1913 revolutionized coinage by introducing advanced minting techniques. Similarly, emerging technologies today promise to redefine manufacturing standards. You can expect the J3L-IF10-FB process to evolve, incorporating tools like 3D printing and IoT devices.

These advancements not only address current limitations but also unlock new possibilities. You will benefit from products that are more reliable, affordable, and environmentally friendly. The future of the J3L-IF10-FB production process holds immense potential, driven by the continuous integration of innovative technologies.

The J3L-IF10-FB production process showcases a remarkable blend of efficiency, innovation, and sustainability. You have seen how it transforms raw materials into high-quality products while meeting the demands of modern industries. Its role as a mainstream production process highlights its reliability and adaptability across various sectors.

What sets this process apart are its unique advancements, such as modular assembly lines and AI-driven optimization. These elements make it both practical and fascinating. As technology evolves, you can expect this process to lead the way in shaping the future of manufacturing with even greater possibilities.

See Also

Top J3L-IF10-FB Product Variants You Should Know

Different Variants of the J3L-IF10-FB Product Line

Harnessing SEMTECH's Video Processing Capabilities with GS2972-IBE3