What is the mainstream ECS-F1HE335K production process?

The mainstream ECS-F1HE335K production process focuses on precision, innovation, and efficiency. It ensures high-quality manufacturing by streamlining operations and reducing waste. This process uses advanced technologies like automation and robotics to maintain reliability and performance. Its structured stages guarantee consistent results, making it a benchmark for modern industrial standards.

Key Takeaways

- Use top-quality materials to make sure products last and work well.

- Use machines and robots to work faster, save money, and keep quality high.

- Always improve methods to meet new needs and stay successful.

Key Stages of the Mainstream ECS-F1HE335K Production Process

Material Selection and Preparation

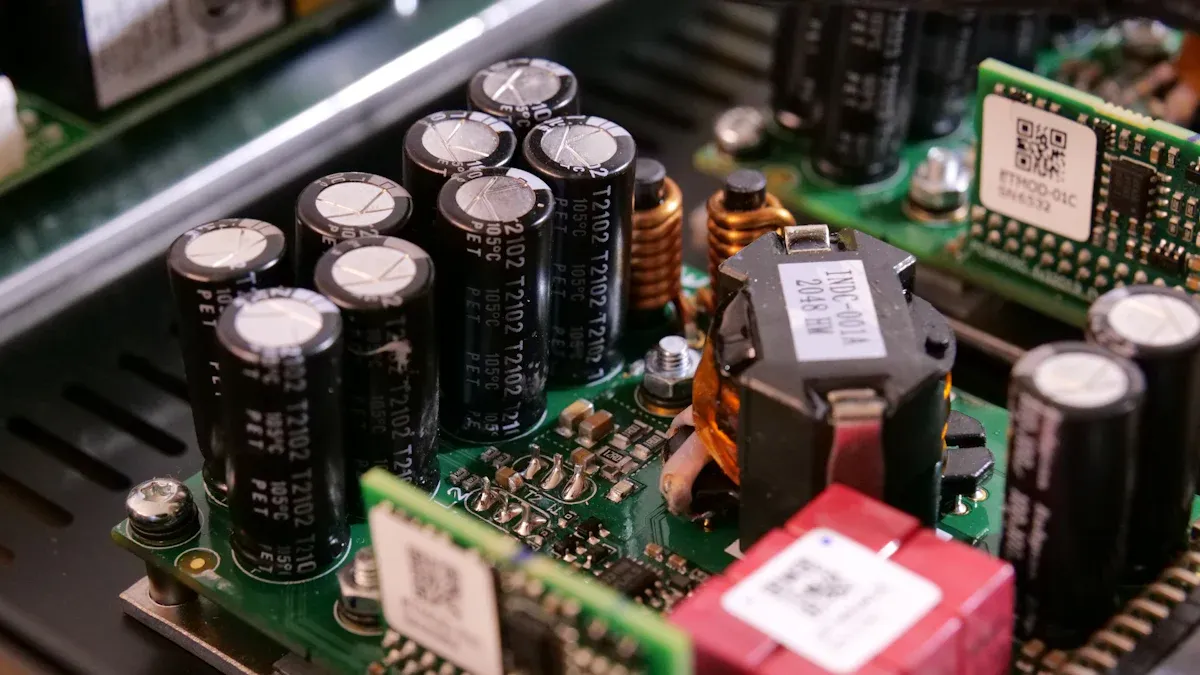

The production of the mainstream ECS-F1HE335K begins with selecting high-quality materials. You’ll find that manufacturers prioritize materials with excellent electrical properties and the ability to withstand environmental stress. This ensures the final product meets durability and performance standards. Once selected, the raw materials undergo preparation processes like cleaning, shaping, and treating. These steps remove impurities and enhance compatibility with manufacturing requirements. By starting with well-prepared materials, you set the stage for reliable and efficient components.

Component Manufacturing and Assembly

The manufacturing and assembly stage involves several precise steps:

- Material selection ensures durability and performance.

- Preparation eliminates impurities and optimizes materials for production.

- Advanced machinery assembles components with precision.

- Rigorous testing verifies performance.

- Calibration fine-tunes components for optimal operation.

Each step contributes to the consistent quality of the mainstream ECS-F1HE335K components.

Testing and Calibration

Testing and calibration play a critical role in ensuring the reliability of each component. Manufacturers use advanced methods like X-ray imaging, ultrasonic analysis, and automated inspections to detect defects. Non-destructive testing ensures components meet industry standards without damage. Calibration evaluates capacitance, energy storage, and durability. This process fine-tunes components to meet specific operational requirements, ensuring they perform consistently in real-world applications.

Packaging and Distribution

Proper packaging and distribution protect the mainstream ECS-F1HE335K components during transit. Secure packaging materials like anti-static bags and foam inserts shield components from environmental factors. Clear labeling with product specifications and batch numbers streamlines inventory management. Reliable logistics partners and advanced tracking systems ensure timely delivery and real-time shipment monitoring. These strategies maintain product quality and ensure efficient distribution.

Technologies Driving the Mainstream ECS-F1HE335K Production Process

Automation and Robotics

Automation and robotics play a pivotal role in the mainstream ECS-F1HE335K production process. These technologies enhance precision and speed, ensuring consistent quality in every component. Automated systems handle repetitive tasks with unmatched accuracy, reducing human error and improving efficiency. Robotics also excel in assembling intricate components, maintaining uniformity across production batches.

- Key benefits of automation include:

- Faster manufacturing processes.

- Reduced labor costs and material waste.

- Scalability to meet increased production demands.

- Improved product quality through consistent assembly.

By integrating automation and robotics, you can achieve cost-effective production while maintaining high standards.

Advanced Manufacturing Techniques

Advanced manufacturing techniques elevate the mainstream ECS-F1HE335K production process by combining innovation with sustainability. Automation and robotics streamline repetitive tasks, ensuring precision and speed. Non-destructive testing methods, such as X-ray imaging, detect defects without damaging components, guaranteeing reliability. Additionally, energy-efficient machinery and material recycling reduce environmental impact. These techniques not only improve product quality but also lower production costs by minimizing waste and optimizing resources.

Data Integration and Monitoring

Data integration and monitoring ensure seamless operations in the mainstream ECS-F1HE335K production process. Real-time data collection allows you to track every stage of production, from material preparation to final packaging. Advanced monitoring systems identify inefficiencies and predict potential issues, enabling proactive solutions. By analyzing production data, manufacturers can optimize workflows, reduce downtime, and maintain consistent quality. This data-driven approach ensures that the production process remains efficient and adaptable to changing demands.

Quality Assurance in the Mainstream ECS-F1HE335K Production Process

Inspection and Testing Protocols

Inspection and testing protocols ensure the quality of every component in the mainstream ECS-F1HE335K production process. You’ll find that inspections occur at every stage to identify and resolve potential issues early. These include:

- Visual inspections to detect surface defects.

- Automated checks for precision and consistency.

- Functional tests to verify performance under real-world conditions.

Advanced tools like optical scanners and automated testing systems enhance accuracy and reduce human error. Testing methods such as X-ray imaging and ultrasonic analysis further ensure that components meet industry standards without damage. By implementing these protocols, you can maintain the reliability and performance of the final product.

Standards Compliance

Adhering to strict industry standards is essential for the mainstream ECS-F1HE335K production process. Certifications like ISO provide a framework for maintaining consistency and reliability. These standards ensure that every component meets safety and quality requirements, building trust with customers. Compliance also enhances the reputation of your products, proving their reliability in global markets.

By following these guidelines, you not only meet regulatory requirements but also demonstrate a commitment to excellence. This approach ensures that your products remain competitive and trusted worldwide.

Continuous Improvement Practices

Continuous improvement practices keep the mainstream ECS-F1HE335K production process efficient and innovative. Feedback loops play a crucial role by collecting insights from customers, production teams, and testing results. This information helps you identify areas for enhancement and refine processes to address recurring issues.

Investing in training and development for your team ensures they stay updated on the latest techniques. Regular training sessions foster a culture of excellence and innovation. By prioritizing continuous improvement, you can adapt to changing demands and maintain high-quality standards over time.

The mainstream ECS-F1HE335K production process combines structured stages, advanced technologies, and rigorous quality measures to deliver reliable components. Innovation drives efficiency by fostering a culture of excellence, leveraging automation for precision, and using advanced equipment for defect detection. These practices ensure consistent quality while adapting to evolving demands, maintaining high standards in every product.

FAQ

What makes the ECS-F1HE335K production process unique?

The process combines advanced technologies like automation, non-destructive testing, and data monitoring. These ensure precision, efficiency, and consistent quality in every component.

How does automation improve production efficiency?

Automation speeds up repetitive tasks, reduces errors, and ensures consistent assembly. It also lowers costs and allows you to scale production to meet growing demands. 🚀

Why is quality assurance essential in this process?

Quality assurance ensures components meet industry standards. It builds trust, enhances reliability, and prevents defects from reaching customers, maintaining your product's reputation in competitive markets.

See Also

Comparing Variations Among ST-4ETD202 Model Offerings

A Deep Dive Into EP4CE6E22C8N Cyclone IV FPGA Details

Key Characteristics of the SMT35A-102LF Product Line

Distinctive Aspects of the SMT35A-102LF Standards Explained

GS2972-IBE3: Revealing SEMTECH's Video Processing Capabilities