How to Design a 4-20mA Current Loop with the XTR111AIDGQR

The 4-20mA current loop is a common way to send signals in factories. It helps devices talk to each other accurately, even far apart. This system is great for controlling and checking processes. It can find broken wires and keep signals clear, making it very useful.

The XTR111AIDGQR is key to building a strong 4-20mA current loop. It changes voltage signals into exact current outputs for steady work. New tech like Ethernet-APL improves safety, but old 4-20mA systems are still important. They work well with Ethernet networks, even in risky areas.

When making your current loop, the XTR111AIDGQR gives great accuracy and strength, perfect for factory jobs.

Key Takeaways

The 4-20mA current loop is important for sending signals in factories. It helps send accurate messages over long distances.

The XTR111AIDGQR changes voltage signals into steady currents. This makes sure signals are correct and not affected by noise.

Using a 4mA 'Live Zero' can find problems like broken wires. This improves how well the system works.

Picking the right power supply and resistors is key. It keeps the signal strong and stops voltage problems in the loop.

Testing and adjusting system parts often keeps them accurate. This helps avoid sudden breakdowns.

Basics of the 4-20mA Current Loop

What It Is and How It Works

The 4-20mA current loop is a common way to send signals in factories. It changes things like temperature or pressure into a matching current. The current goes from 4mA (lowest) to 20mA (highest). If the current drops below 4mA, it shows there’s a problem, like a broken wire.

This system is simple to understand. It follows Ohm’s Law: voltage equals current times resistance. The current stays the same through the loop, keeping signals accurate. A basic setup has a power supply, a transmitter, and a resistor, all connected in a line. This setup sends signals far without losing accuracy.

Why Current Signals Are Better

Current signals work better than voltage signals in factories. They don’t lose strength over long wires. They also ignore electrical noise, so signals stay clear. The 4mA starting point helps find problems, like broken wires or bad sensors.

Benefit | Explanation |

|---|---|

Long Distance Signals | Current travels far without losing strength. |

Noise Resistance | Electrical noise doesn’t mess up current signals. |

Problem Detection | The 4mA starting point shows issues like broken wires. |

Steady Accuracy | Current stays stable, even with long wires or resistance. |

Widely Used | The 4-20mA system works with many devices. |

Where It’s Used

Factories use the 4-20mA loop to check and control machines. It links sensors to controllers, like SCADA or PID systems, for accurate data. Factories use it to measure things like temperature, pressure, and flow. It’s simple and tough, so it works well in hard conditions.

For example, food factories use it to watch their processes. Sensors with screens show live data, helping workers act fast. The loop can also power devices, so less wiring is needed.

Components for a 4-20mA Current Loop

Role of the XTR111AIDGQR

The XTR111AIDGQR is important for making a steady 4-20mA loop. It changes voltage into current, keeping signals accurate and stable. This device has a built-in circuit to measure current, so no extra resistors are needed. It works well in tough factory settings, giving precise and trustworthy data.

You can adjust the XTR111AIDGQR to fit your needs. It handles input voltages from 4.75V to 36V, making it flexible. It also resists interference, so it works fine in noisy places. These features make it great for factory systems that monitor and control machines.

Feature | Description |

|---|---|

Built-in current sampling circuit | Measures current directly for better accuracy and stability. |

High-precision measurement | Uses advanced tech to keep data reliable. |

Programmability | Lets you change input and output settings as needed. |

Low power consumption | Saves energy and helps devices last longer. |

High linearity | Keeps signals clear without distortion. |

Wide input voltage range | Works with voltages from 4.75V to 36V for many uses. |

Strong anti-interference ability | Stays stable even in areas with lots of electrical noise. |

Sensors and Signal Input

Sensors start the 4-20mA loop by turning things like heat or pressure into signals. The transmitter then changes these signals into matching currents. For example, a temperature sensor in an HVAC system sends data to control equipment.

The 4-20mA loop has been used since the 1960s because it keeps signals clear over long distances. Common sensors include those for temperature, pressure, and humidity. These are used in factories, HVAC systems, and environmental checks.

Sensor Type | Application |

|---|---|

Temperature | HVAC systems |

Pressure | Industrial processes |

Humidity | Environmental monitoring |

Resistors for Current Regulation

Resistors help control current and make sure devices work right. The load resistor sets the voltage, which affects signal accuracy. For instance, a 250 Ohm resistor gives a 1-5 VDC range, often used in systems. Picking the right resistor ensures the loop works well.

Using a 4mA "Live Zero" improves signal clarity and finds problems like broken wires. Check the transmitter's voltage limits when designing. For example, a 15VDC supply with a 330 Ohm load might cause issues. A transmitter like the XTR111AIDGQR, which works with low voltage, avoids these problems.

Tips for choosing resistors:

Match the resistor to the system's voltage needs.

Use a "Live Zero" to spot failures and improve reliability.

Check voltage limits to prevent performance problems.

Power Supply Considerations

The power supply is very important for the 4-20mA loop. Picking the right one helps all parts work well. It must match the needed voltage for the system.

Here are things to think about when choosing a power supply:

Voltage Requirements: The power supply must give enough voltage for the system. This includes drops from the shunt resistor, wires, and transmitter or sensor. For example, a 249 Ω shunt resistor adds to the voltage drop.

Wire Resistance: Long wires add resistance, which lowers voltage. A 2000 ft 24-gauge wire adds about 2.1 V drop. You need to include this in your plan to avoid problems.

Recommended Voltage: A 24 V power supply works well for most factory setups. It handles voltage drops and keeps devices like sensors working properly.

System Stability: A steady power supply keeps signals accurate. Use regulated supplies to reduce noise and voltage changes.

💡 Tip: Always check the total voltage drop before picking a power supply. This keeps your system reliable, even with long wires.

By thinking about these points, you can make a strong 4-20mA loop for factory use.

Designing the 4-20mA Current Loop

Voltage-to-Current Conversion Setup

To make a reliable 4-20mA loop, you need the right setup. This setup changes voltage signals from sensors into current signals for factory use. The XTR111AIDGQR is key because it turns voltage into exact current.

A basic setup has a DC power supply, a transducer, wires, and a data device. The transducer adjusts current between 4mA (low) and 20mA (high). If the loop breaks, the current drops to 0mA, showing a problem. A shunt resistor changes current into voltage for easy measurement.

Benefits of this setup include:

Clear signals over long distances.

Easy to use in many factory setups.

Works with different power supplies.

💡 Tip: Use good parts to avoid signal problems and keep current steady.

Configuring the XTR111AIDGQR

The XTR111AIDGQR makes setting up your 4-20mA loop simple. It handles voltage-to-current changes with great accuracy, perfect for factories.

Steps to set up the XTR111AIDGQR:

Link the sensor's voltage output to the device.

Adjust the input voltage to fit your system (4.75V to 36V).

Set the output current to match the 4-20mA range.

Ground the device to reduce noise and interference.

The XTR111AIDGQR has a built-in circuit to measure current, so no extra resistors are needed. You can adjust settings to fit your needs. It also works well in noisy places, keeping signals stable.

Feature | Benefit |

|---|---|

Built-in current sampling circuit | Makes setup easier and improves accuracy. |

Programmability | Lets you adjust settings for specific needs. |

High linearity | Keeps signals clear and accurate. |

Wide input voltage range | Works with many factory systems. |

💡 Note: Test the device often to ensure the current output is correct.

Connecting the Loop Components

After setting up the voltage-to-current system and XTR111AIDGQR, connect the loop parts. Good connections help the system work smoothly and send accurate signals.

Steps to connect the loop:

Connect the DC power supply to the transmitter.

Attach the sensor to the transmitter for input signals.

Link the XTR111AIDGQR to the transmitter for current conversion.

Add a shunt resistor to measure current and turn it into voltage.

Use strong wires to connect everything and avoid signal loss.

Common design tips include using transistors to control current, amplifiers for voltage, and resistors for measurement. Temperature adjustments help keep accuracy in different conditions.

Design Strategy | Description |

|---|---|

Use of Transistors | Controls current flow for smooth operation. |

Operational Amplifiers | Manages voltage and keeps signals steady. |

Current Sources | Provides steady current in changing conditions. |

Sense Resistors | Measures current and manages voltage drops. |

Power Supply Configuration | Prevents noise and keeps voltage steady. |

Common Mode Error Management | Fixes errors in 2-wire setups for better reliability. |

Temperature Compensation | Keeps accuracy when temperatures change. |

💡 Tip: Check all connections to avoid loose wires or wrong resistor placement.

By following these steps, you can build a strong 4-20mA loop for accurate factory measurements and controls.

Calculating Key Parameters

When making a 4-20mA current loop, you need to calculate important parts. These steps help you pick the right resistors, check voltage drops, and choose the correct power supply. Let’s go through the basics.

1. Finding the Load Resistor Value

The load resistor changes the current into a voltage you can measure. Use this formula:

R = V / I

Here:

Ris the resistor value in ohms (Ω).Vis the voltage across the resistor.Iis the current (4-20mA).

For example, if you want 1-5V:

At 4mA: ( R = 1V / 0.004A = 250Ω )

At 20mA: ( R = 5V / 0.02A = 250Ω )

So, a 250Ω resistor works well. Pick a resistor with a higher power rating to last longer.

2. Checking Voltage Drop in the Loop

Voltage drop is the total voltage used by all parts of the loop. This includes the resistor, wires, and transmitter. Use this formula:

V_drop = I * R_total

Where:

Iis the current (4-20mA).R_totalis the total resistance in the loop.

For example, if the resistance is 300Ω and the current is 20mA:

( V_drop = 0.02A * 300Ω = 6V )

Make sure your power supply gives enough voltage for this drop and powers the transmitter.

3. Choosing the Power Supply

The power supply must give enough voltage and current for the loop. Use this formula:

V_supply = V_drop + V_transmitter

For example, if the voltage drop is 6V and the transmitter needs 12V:

( V_supply = 6V + 12V = 18V )

A 24V power supply is common in factories. It handles extra voltage drops and keeps the system steady.

4. Managing Current Control

The XTR111AIDGQR makes current control easy. It turns voltage into accurate current automatically. You don’t need to adjust it yourself. Just make sure the input voltage and output current match your system.

💡 Tip: Always check your math and test the loop to ensure it works well.

Example Table: Key Parameter Calculations

Parameter | Formula | Example Calculation | Result |

|---|---|---|---|

Load Resistor (R) | ( R = V / I ) | ( R = 5V / 0.02A ) | 250Ω |

Voltage Drop (V_drop) | ( V_drop = I * R_total ) | ( V_drop = 0.02A * 300Ω ) | 6V |

Power Supply (V_sup) | ( V_sup = V_drop + V_tx ) | ( V_sup = 6V + 12V ) | 18V |

By following these steps, you can calculate the key parts for a strong 4-20mA current loop. These calculations help your system work smoothly and give accurate results.

Practical Example with the XTR111AIDGQR

Example Circuit Design

Let’s see how the XTR111AIDGQR works in a 4-20mA loop. This example shows how to turn a voltage signal from a temperature sensor into a current signal for monitoring.

The circuit uses these parts:

A 24V DC power supply to run the loop.

A temperature sensor that gives a voltage based on temperature.

The XTR111AIDGQR to change the voltage into a 4-20mA current.

A 250Ω shunt resistor to turn the current back into a voltage for reading.

Wires to connect everything together.

The XTR111AIDGQR keeps the current steady and accurate, even in noisy places. This is important for tracking temperature changes reliably.

💡 Tip: Use good-quality parts to avoid signal problems and ensure the circuit lasts.

Component Breakdown

When building a circuit with the XTR111AIDGQR, pick the right parts for your needs. Here’s what each part does:

XTR111AIDGQR:

Changes the sensor’s voltage into a precise 4-20mA current.

Works well in factories because it’s stable and accurate.

Temperature Sensor:

Measures temperature and gives a matching voltage signal.

Examples include thermocouples and RTDs.

Shunt Resistor:

Turns the 4-20mA current into a voltage for easy measurement.

A 250Ω resistor is common for a 1-5V output.

Power Supply:

Provides the needed voltage for the loop.

A 24V supply is standard for most setups.

Wires:

Connect all parts and keep the loop complete.

Use low-resistance wires to reduce voltage loss.

Choose parts based on where and how the circuit will be used. For example, if it’s in a hot area, pick heat-resistant components.

Step-by-Step Implementation

Follow these steps to set up the 4-20mA loop with the XTR111AIDGQR:

Preparation:

Gather all parts: XTR111AIDGQR, sensor, power supply, and resistor.

Check the XTR111AIDGQR datasheet for pin details and conditions.

Assemble the Circuit:

Connect the sensor’s voltage output to the XTR111AIDGQR input.

Place the shunt resistor across the output to measure current.

Attach the power supply to the XTR111AIDGQR, ensuring correct polarity.

Turn on the circuit and check the current at different sensor outputs.

Make sure the current stays between 4mA and 20mA.

Use a multimeter to measure the voltage across the resistor.

Troubleshooting:

If the current isn’t in the 4-20mA range, check the sensor and XTR111AIDGQR settings.

Ensure all connections are tight and clean.

Final Steps:

Once it works, write down the setup for future use.

Add the circuit to your system and test it in real conditions.

💡 Note: Calibrate the circuit often to keep it accurate over time.

By following these steps, you can build a reliable 4-20mA loop to monitor temperature or other data. This setup ensures clear and accurate signals, even in tough factory environments.

Troubleshooting and Optimization

Common Problems and Fixes

When using a 4-20mA current loop, problems can happen. These often come from noise, bad wiring, or broken parts. Fixing them quickly keeps your system working well.

Power Supply Noise: Noise from the power supply can mess up the loop. Add a 10µF ceramic capacitor near the power supply input to reduce noise. Also, place a 1µF ceramic capacitor with each shunt resistor. These changes make the system more stable.

Wiring Mistakes: Loose or wrong wires can cause bad readings. Check all wires and follow the circuit diagram carefully.

Broken Parts: Bad resistors or transmitters can cause problems. Use a Fishbone diagram to find the issue. Group discussions can also help solve these problems.

💡 Tip: Check your loop parts often to avoid sudden failures.

Keeping Accuracy and Stability

Good accuracy is key for correct measurements in your loop. Testing and calibration are very important.

Test all parts of the loop, not just one device. For example, check temperature probes for correct readings.

Do loop tests to confirm accurate flow readings in complex setups.

Calibrate devices like transmitters often. Over time, they can drift and give wrong outputs.

Work with engineers to set limits for your system. Think about long-term stability and repeatability.

🔧 Note: Regular calibration keeps your system accurate and dependable.

Improving for Factory Use

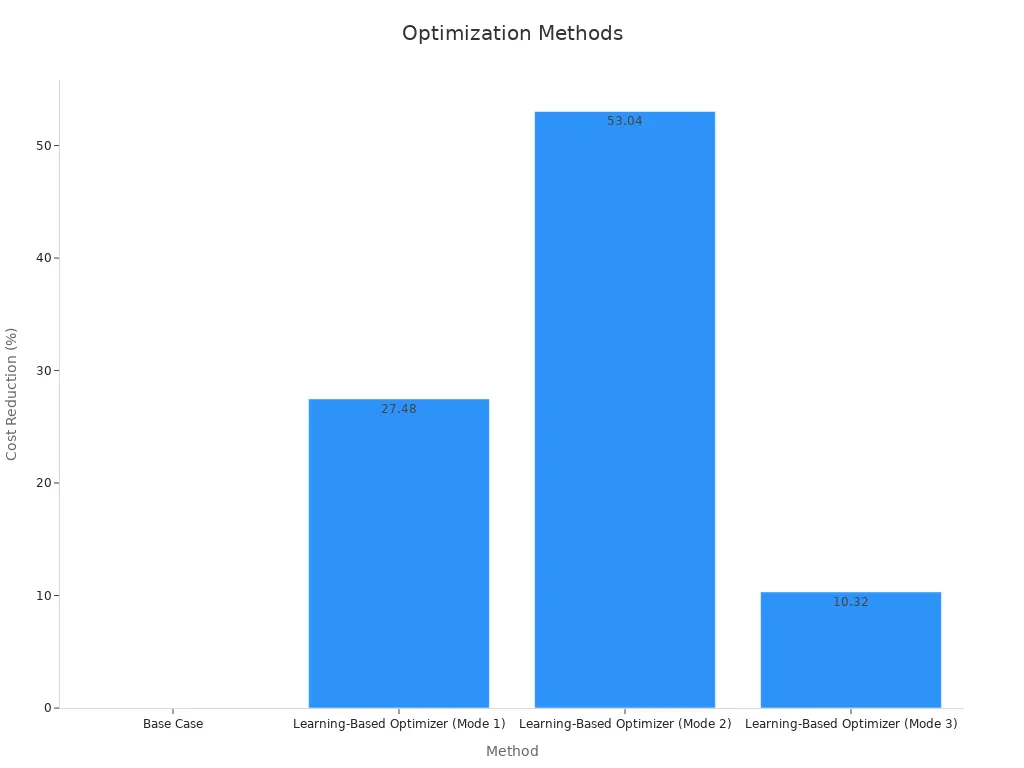

To make your loop better for factories, focus on saving money and boosting efficiency. Advanced methods can help.

Method | Cost Savings (%) |

|---|---|

Learning-Based Optimizer (Mode 1) | 27.48 |

Learning-Based Optimizer (Mode 2) | 53.04 |

Learning-Based Optimizer (Mode 3) | 10.32 |

Using learning-based tools can save money and improve performance. For example, adding a deep network can increase efficiency by 13%.

💡 Tip: Use real-time monitoring with smart tools to make your system better for factory work.

By fixing problems, keeping accuracy, and improving for factories, you can create a strong and efficient 4-20mA current loop.

Making a 4-20mA current loop means knowing its parts, setting up the XTR111AIDGQR, and connecting everything correctly. This helps send signals accurately and keeps the system working well in factories. The XTR111AIDGQR is a helpful and flexible tool for this job. It makes setup easier while keeping signals clear and steady.

Feature | Benefit |

|---|---|

Low power use | Saves energy and helps devices last longer. |

High accuracy | Keeps measurements correct and avoids signal errors. |

Wide voltage range | Works in many setups without needing constant changes. |

Strong noise resistance | Stays steady even in noisy places with lots of interference. |

Built-in current checker | Makes design simple and measures current more accurately. |

Precise measurements | Tracks small and big current changes for better data. |

Easy to program | Lets you adjust settings to fit different needs. |

Using these features, you can build a strong system for your needs. Try different setups and use the XTR111AIDGQR’s advanced options to make your design better for factory work.

FAQ

Why is the XTR111AIDGQR good for factories?

The XTR111AIDGQR is accurate, uses little power, and blocks noise. It works in tough places and handles many voltage levels. These features make it great for factory systems needing steady and exact current loops.

Can the XTR111AIDGQR send signals far?

Yes, the XTR111AIDGQR keeps signals steady over long distances. Its design stops signal loss and blocks interference. This makes it perfect for factories with far-apart devices.

How do you fix problems in a 4-20mA loop?

First, check the power supply and all connections. Use a multimeter to test current and voltage at key spots. Replace broken parts like resistors or sensors. Add capacitors if there’s too much noise.

💡 Tip: Regular checks stop most problems before they happen.

What sensors work with the XTR111AIDGQR?

The XTR111AIDGQR works with sensors that give voltage signals. Examples are temperature, pressure, or humidity sensors. These sensors turn physical data into electrical signals.

How do you find the right resistor value?

Use this formula: ( R = V / I ). Here, ( V ) is the voltage you want, and ( I ) is the current (4-20mA). For example, to get 1-5V output, use a 250Ω resistor.

🔧 Note: Pick a resistor with a higher power rating so it lasts longer.

See Also

Unveiling The Signal Distribution Wonder Of CDCL6010RGZR

Discover The Precision Motion Sensing Power Of ADXRS453BRGZ

Achieving Accurate Voltage Monitoring With MCP130T-300I/TT

Investigating The Versatile Uses Of LM358DR Operational Amplifier