What are the product standards for the classification of resistors?

Resistors play a crucial role in electronics, serving as fundamental components in various devices. They regulate voltage and current, ensuring the proper functioning of electronic circuits. The demand for resistors has surged with the widespread use of electronic gadgets and the rollout of 5G technology. Standards for resistors, such as IEC and ANSI, ensure quality and consistency across products. These standards help maintain reliability in consumer electronics, which dominated the market with a 48% share in 2023. Understanding the product standards for the classification of resistors, or 电阻器的分类的产品标准有哪些?, is essential for anyone involved in electronics.

Overview of Resistor Standards

International Standards

IEC Standards

The International Electrotechnical Commission (IEC) sets global standards for resistors. One key standard, IEC 60115-1:2020, applies to fixed resistors used in electronic equipment. It establishes standard terms and inspection methods, ensuring consistency and reliability. Another important standard, IEC 60062, defines marking codes for resistors and capacitors. This includes color codes and numerical codes, which help identify resistance values and tolerances.

ANSI Standards

The American National Standards Institute (ANSI) provides guidelines that align with international practices while addressing specific needs in the United States. ANSI standards ensure that resistors meet quality and safety requirements, supporting their effective use in various applications.

National Standards

Country-specific Standards

Different countries have their own standards for resistors. For example, Japan uses the Japanese Industrial Standards (JIS), while Germany follows the Deutsches Institut für Normung (DIN). These standards cater to local industry needs and technological advancements, ensuring that resistors perform optimally in specific environments.

Comparison of National Standards

National standards may vary in aspects like tolerance and marking codes. For instance, the color bands on resistors might differ slightly between countries, affecting how resistance values are read. Understanding these differences is crucial for engineers working with international components, as it ensures compatibility and accuracy in electronic circuits.

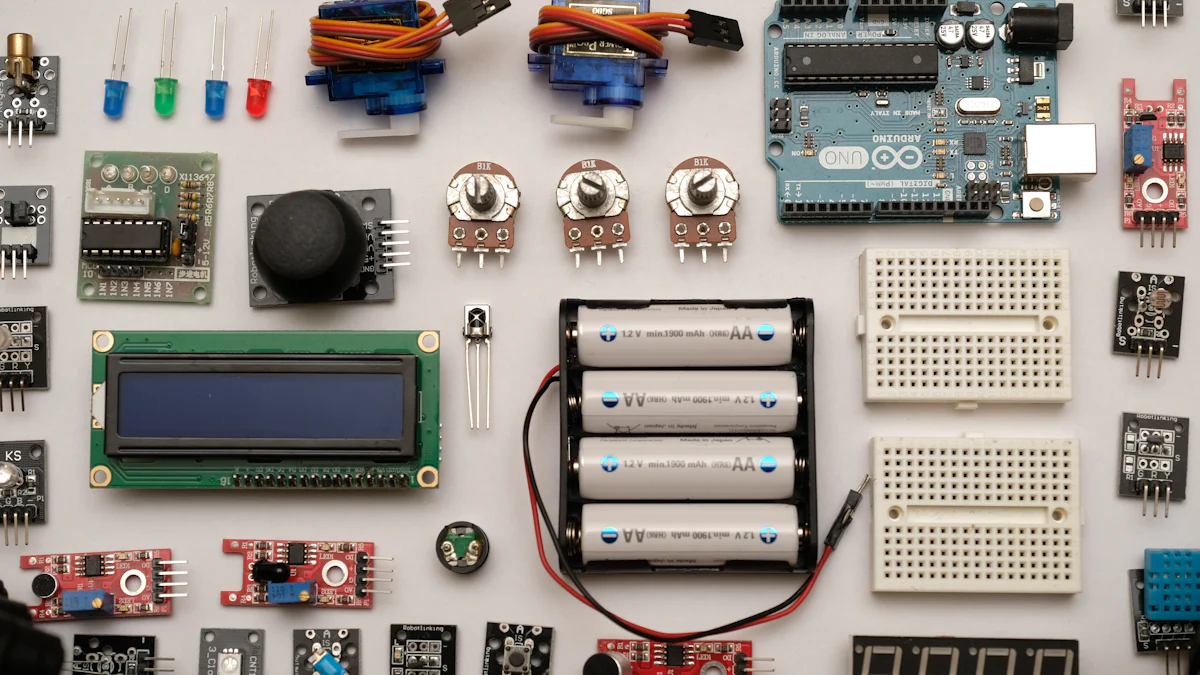

Classification of Resistors

Resistors, essential components in electronic circuits, come in various types. Their classification depends on material composition and functionality. Understanding these categories helps in selecting the right resistor for specific applications.

Based on Material Composition

Carbon Composition Resistors

Carbon Composition Resistors consist of a mixture of carbon powder and a binding resin. This combination forms a resistive element. These resistors offer high energy dissipation and are suitable for applications requiring high pulse stability. However, they exhibit higher noise levels and less precision compared to other types. Engineers often use them in circuits where precision is not critical.

Metal Film Resistors

Metal Film Resistors provide better stability and precision than carbon-based resistors. Manufacturers create them by depositing a thin film of metal onto a ceramic substrate. This construction results in a resistor with excellent temperature characteristics and low noise levels. They are ideal for high-frequency circuits and precision instrumentation. The metal film offers a small temperature coefficient and a large operating frequency range, making them suitable for audio applications as well.

Based on Functionality

Fixed Resistors

Fixed Resistors have a set resistance value that does not change. They are the most common type of resistor used in electronic circuits. These resistors ensure consistent performance and are available in various sizes and power ratings. Engineers use them in applications where a constant resistance is required, such as in voltage dividers and biasing circuits.

Variable Resistors

Variable Resistors, also known as potentiometers or rheostats, allow for adjustable resistance. Users can change the resistance by rotating a knob or sliding a control. This adjustability makes them useful in applications requiring fine-tuning, such as volume controls in audio equipment or adjusting signal levels in circuits. Variable resistors provide flexibility in circuit design, enabling precise control over electrical parameters.

Detailed Description of Resistor Types

Surface Mount Resistors

Characteristics

Surface mount resistors (SMRs) are compact and designed for automated assembly. They adhere to the JEDEC standard, ensuring uniformity in shape and size. These resistors offer high precision and stability, making them ideal for modern electronics. Their small size allows for efficient use of space on printed circuit boards (PCBs).

Applications

SMRs find extensive use in consumer electronics, such as smartphones and laptops. Their precision and reliability make them suitable for high-frequency applications. Engineers often choose SMRs for devices requiring compact design and efficient performance.

Through-Hole Resistors

Characteristics

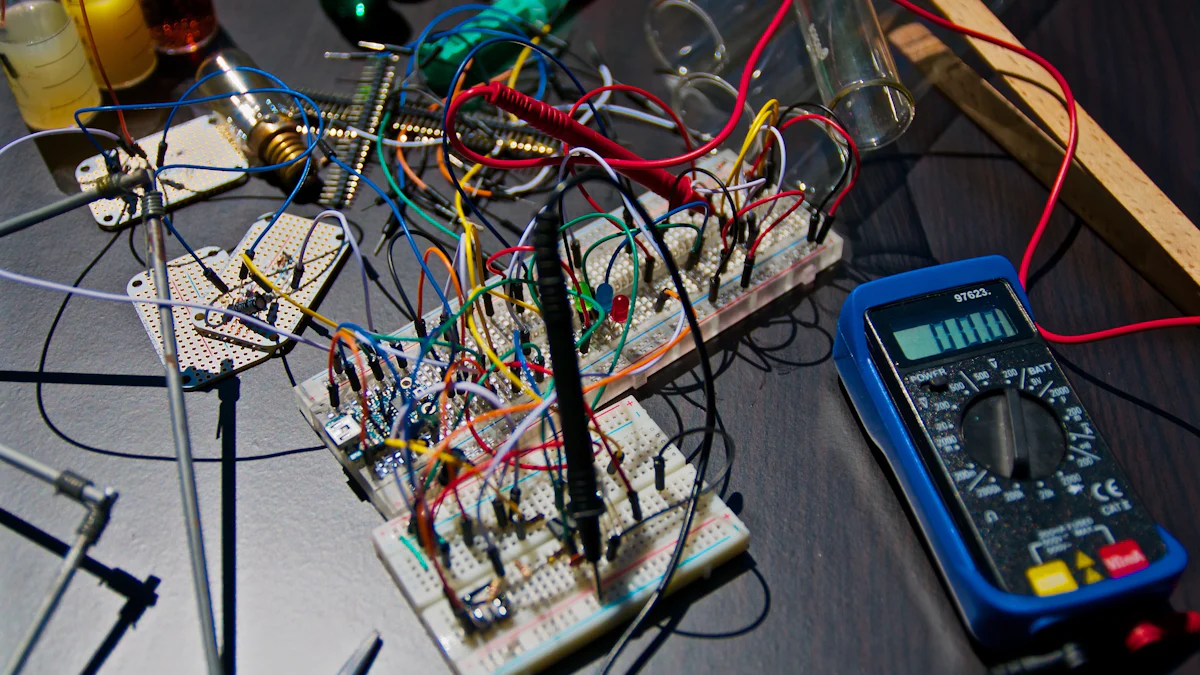

Through-hole resistors feature leads that pass through holes in PCBs. They provide strong mechanical bonds, making them durable and reliable. These resistors come in various sizes and power ratings, offering flexibility in design.

Applications

Through-hole resistors are commonly used in industrial equipment and power supplies. Their robust construction suits environments where durability is crucial. They are also favored in prototyping and testing due to their ease of handling and replacement.

Applications of Different Resistor Types

Consumer Electronics

Common Uses

Resistors play a vital role in consumer electronics. They are integral to devices like smartphones, laptops, and home appliances. These components help regulate voltage and current, ensuring devices operate efficiently. In smartphones, resistors manage power distribution, contributing to battery life and performance. Laptops rely on resistors for stable operation, particularly in managing heat and energy consumption. Home appliances, such as refrigerators and washing machines, use resistors to control electrical flow, enhancing safety and functionality.

Benefits

The benefits of using resistors in consumer electronics are numerous. They enhance energy efficiency, which is crucial for battery-powered devices. By regulating current, resistors prevent overheating, extending the lifespan of electronic components. This reliability ensures that devices perform optimally over time. Additionally, resistors contribute to the miniaturization of electronics, allowing manufacturers to produce compact and lightweight gadgets. This trend meets consumer demand for portable and convenient technology.

Industrial Applications

Common Uses

In industrial settings, resistors are indispensable. They are used in machinery, power supplies, and control systems. Industrial equipment often requires precise control of electrical parameters, and resistors provide this capability. For example, in motor drives, resistors help manage speed and torque. Power supplies use resistors to stabilize voltage levels, ensuring consistent performance. Control systems rely on resistors for accurate signal processing, which is essential for automation and monitoring.

Benefits

Resistors offer significant advantages in industrial applications. They enhance the durability and reliability of equipment, which is critical in demanding environments. By controlling electrical flow, resistors reduce the risk of component failure, minimizing downtime and maintenance costs. This reliability supports continuous operation, which is vital for productivity. Furthermore, resistors contribute to energy savings, aligning with industry goals for sustainability and cost efficiency. Their robust construction makes them suitable for harsh conditions, ensuring long-term performance.

Advantages and Disadvantages of Resistor Types

Advantages

Cost Efficiency

Fixed resistors dominate the market due to their reliability and cost-effectiveness. They provide consistent performance across various applications, making them a popular choice for engineers.

Metal film resistors offer excellent stability and low noise levels. Although they are more expensive than carbon film resistors, their precision and reliability justify the cost in high-frequency circuits.

Performance

Thin film resistors excel in applications requiring high stability and precision. Their low temperature coefficients and excellent stability make them ideal for medical devices and aerospace applications.

Metal film resistors provide superior temperature characteristics and current-noise suppression. These qualities make them suitable for audio equipment and precision instruments.

Disadvantages

Limitations

Carbon composition resistors were widely used in the past but have fallen out of favor. They exhibit poor stability over time and are limited to applications where precision is not critical.

Variable resistors, while offering adjustability, may introduce complexity in circuit design. Their use requires careful consideration to ensure proper functionality.

Durability Concerns

Through-hole resistors provide strong mechanical bonds, yet their larger size can limit their use in compact designs. They remain favored in environments where durability is crucial.

Surface mount resistors offer compactness but may face challenges in high-power applications. Their small size can lead to heat dissipation issues if not properly managed.

Resistor standards and classifications play a vital role in ensuring quality and consistency in electronics. They provide a framework that supports reliability and performance across various applications. By adhering to these standards, manufacturers can produce components that meet global expectations.

Resistors remain fundamental in technology, influencing everything from consumer gadgets to industrial machinery. Their ability to regulate electrical parameters ensures the safe and efficient operation of devices. As technology advances, the importance of maintaining ethical standards in resistor production becomes even more crucial, promoting safety and innovation in the tech industry.