3 key development trends in SMT35A-102LF

The SMT35A-102LF industry is undergoing significant changes that you cannot ignore. Three major development trends are shaping its future. First, advancements in miniaturization and precision are driving the demand for smaller, more efficient components. Second, the integration of smart manufacturing and automation is transforming production processes with cutting-edge technologies. Lastly, a growing focus on sustainability is pushing the industry toward eco-friendly materials and energy-efficient practices. These trends directly impact how you approach innovation, production, and long-term success in this evolving field.

Key Takeaways

- Embrace miniaturization: Focus on developing smaller, more efficient components to meet the growing demand in modern electronics.

- Leverage smart manufacturing: Adopt Industry 4.0 technologies like IoT and robotics to enhance production efficiency and reduce costs.

- Integrate AI for quality control: Utilize AI and machine learning to improve defect detection and streamline quality assurance processes.

- Prioritize sustainability: Shift towards eco-friendly materials and processes to align with consumer expectations and regulatory standards.

- Enhance energy efficiency: Implement strategies to reduce energy consumption, which lowers costs and minimizes environmental impact.

- Stay informed: Keep up with industry trends to remain competitive and adapt your strategies for long-term success.

- Invest in training: Equip your workforce with the skills needed to navigate these technological advancements and sustainable practices.

Development Trend 1: Advancements in Miniaturization and Precision

Increasing demand for smaller, more efficient components

The push for smaller, more efficient components has reshaped the SMT35A-102LF industry. You see this demand growing as devices become more compact and multifunctional. Smartphones, wearables, and IoT devices require components that fit into tighter spaces without sacrificing performance. This trend challenges you to innovate and create solutions that meet these evolving needs.

Smaller components offer several advantages. They reduce the overall size of devices, improve portability, and enhance energy efficiency. These benefits make them essential for modern electronics. However, meeting this demand requires advanced manufacturing techniques and precise engineering. You must focus on developing technologies that ensure reliability and functionality in these compact designs.

Challenges in achieving precision at scale

Achieving precision at scale presents unique challenges. As you work with smaller components, even minor errors can lead to significant issues. Maintaining accuracy during mass production becomes critical. You need to adopt cutting-edge tools and processes to ensure consistent quality.

Automation plays a key role in overcoming these challenges. By integrating advanced machinery and robotics, you can achieve the precision required for large-scale production. Additionally, investing in skilled personnel and continuous training helps you stay ahead in this competitive landscape. Precision manufacturing demands a combination of expertise, technology, and attention to detail.

The development trends in miniaturization and precision highlight the importance of innovation. You must adapt to these changes to remain competitive and meet the expectations of modern consumers. By addressing the demand for smaller components and overcoming production challenges, you position yourself for long-term success in this dynamic industry.

Development Trend 2: Integration of Smart Manufacturing and Automation

Adoption of Industry 4.0 technologies

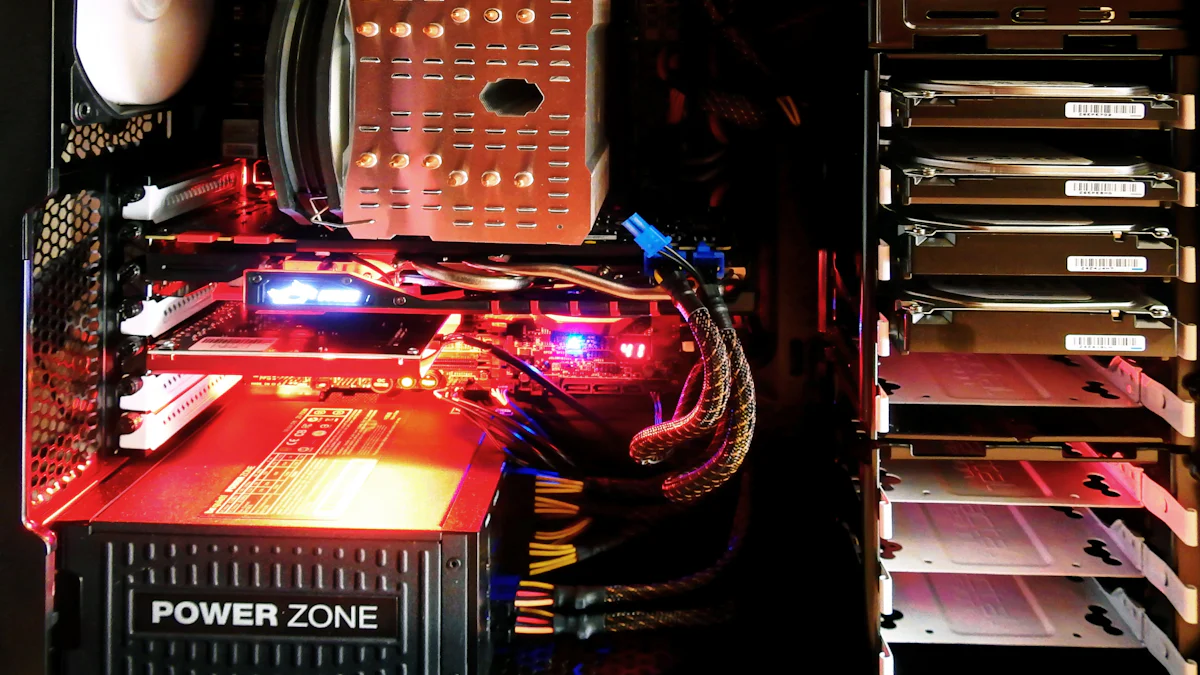

Industry 4.0 technologies are reshaping how you approach manufacturing. These technologies, including the Internet of Things (IoT), cloud computing, and advanced robotics, enable you to create smarter, more efficient production systems. By connecting machines, devices, and systems, you can gather real-time data to monitor and optimize every step of the manufacturing process.

With IoT sensors, you can track equipment performance and detect potential issues before they disrupt production. Cloud computing allows you to store and analyze vast amounts of data, helping you make informed decisions quickly. Robotics enhances precision and speed, reducing errors and improving productivity. These tools work together to streamline operations and reduce costs.

Adopting Industry 4.0 technologies also helps you stay competitive in a fast-changing market. As these development trends continue to evolve, embracing smart manufacturing ensures that your processes remain efficient and adaptable. You gain the ability to respond to customer demands faster and deliver higher-quality products.

The rise of AI and machine learning in quality control

Artificial intelligence (AI) and machine learning are transforming quality control in manufacturing. These technologies allow you to identify defects and inconsistencies with greater accuracy than traditional methods. By analyzing patterns and data, AI systems can detect issues that might go unnoticed by human inspectors.

Machine learning algorithms improve over time as they process more data. This means your quality control systems become smarter and more reliable with continued use. You can use AI-powered cameras and sensors to inspect products in real-time, ensuring that only high-quality items reach your customers.

AI also helps you predict potential problems before they occur. By analyzing historical data, these systems can identify trends and recommend preventive measures. This reduces waste, saves resources, and enhances overall efficiency. As you integrate AI and machine learning into your processes, you position yourself at the forefront of innovation in the SMT35A-102LF industry.

The integration of smart manufacturing and automation highlights the importance of staying ahead of technological advancements. By adopting Industry 4.0 technologies and leveraging AI for quality control, you can improve efficiency, reduce costs, and maintain a competitive edge. These development trends are essential for driving growth and ensuring long-term success in the industry.

Development Trend 3: Growing Focus on Sustainability and Eco-Friendly Practices

Shift toward environmentally friendly materials and processes

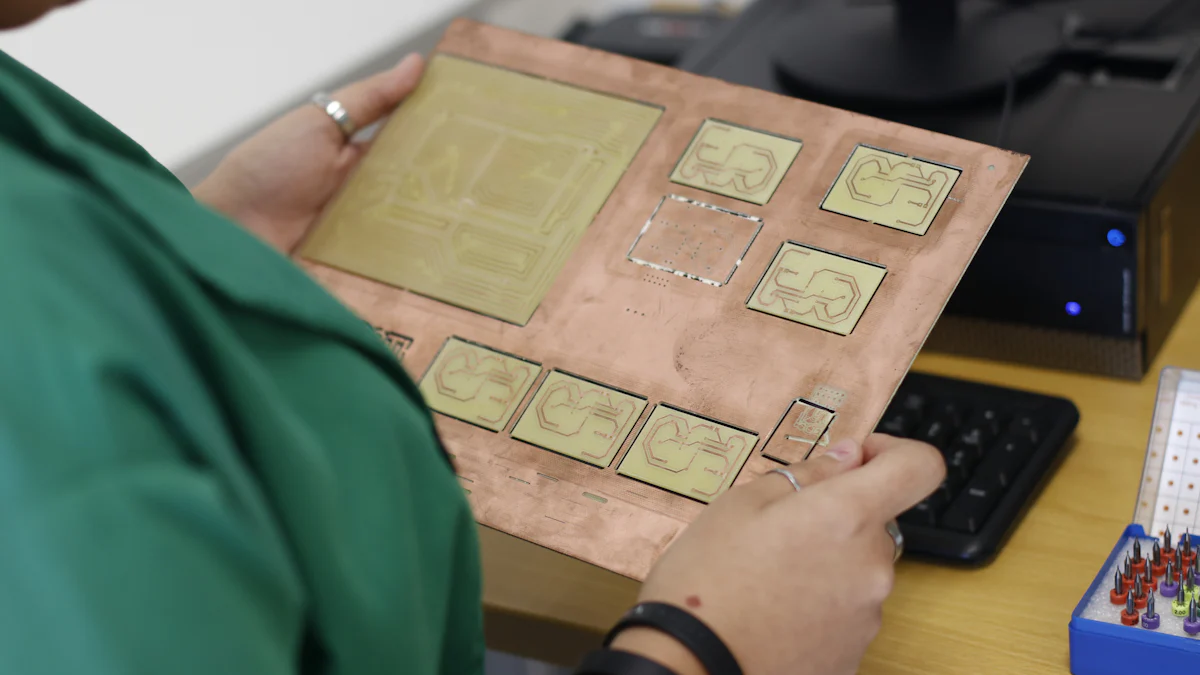

You see a growing emphasis on using environmentally friendly materials in the SMT35A-102LF industry. Manufacturers are moving away from hazardous substances and adopting alternatives that minimize environmental harm. Lead-free solder, biodegradable packaging, and recyclable components are becoming standard choices. These materials not only reduce waste but also align with global regulations and consumer expectations.

Switching to eco-friendly processes is equally important. You can implement cleaner production methods that generate fewer emissions and consume less water. For example, water-based cleaning solutions replace chemical solvents in many facilities. This shift protects ecosystems and improves workplace safety. By prioritizing sustainable practices, you contribute to a healthier planet while meeting the demands of environmentally conscious customers.

Adopting these changes requires effort and investment. You may need to upgrade equipment or retrain your workforce. However, the long-term benefits outweigh the initial costs. Sustainable practices enhance your brand reputation and open doors to new markets. They also prepare you for stricter environmental regulations in the future.

Energy efficiency in manufacturing

Energy efficiency plays a critical role in sustainable manufacturing. Reducing energy consumption lowers your operational costs and decreases your carbon footprint. You can achieve this by optimizing production lines, upgrading to energy-efficient machinery, and using renewable energy sources.

Smart technologies help you monitor and manage energy use effectively. IoT sensors track power consumption in real time, allowing you to identify inefficiencies. Automated systems adjust energy usage based on demand, ensuring no resources go to waste. These tools make your operations more sustainable and cost-effective.

Lighting and HVAC systems also offer opportunities for improvement. Switching to LED lighting and installing programmable thermostats can significantly cut energy use. Small changes like these add up over time, making a big difference in your overall efficiency.

Energy-efficient practices benefit both your business and the environment. They reduce greenhouse gas emissions and conserve natural resources. By focusing on energy efficiency, you align with the broader development trends in sustainability. This approach positions you as a responsible leader in the SMT35A-102LF industry.

The SMT35A-102LF industry is evolving rapidly with three key development trends: miniaturization and precision, smart manufacturing and automation, and sustainability. Adapting to these trends ensures your long-term success in this competitive field. You must embrace advanced technologies to enhance efficiency and precision. Prioritizing eco-friendly practices strengthens your brand and aligns with global expectations. Staying informed about market changes keeps you ahead of the curve. By taking these steps, you position yourself as a leader in innovation and sustainability, ready to meet the demands of the future.

See Also

Exploring The Key Attributes Of SMT35A-102LF

Understanding The Unique Standards Of SMT35A-102LF

The Importance Of SMT35A-102LF In Medical Equipment