3 Steps to Master the Mainstream Production Process

Mastering the mainstream production process is essential for achieving efficiency and success in any industry. By focusing on preparation, execution, and quality assurance, you can streamline workflows and optimize resources. Automation plays a key role here, as it reduces repetitive tasks and enhances productivity. For instance, automating 64 percent of manufacturing tasks can save billions of working hours, while sales departments report a 15 percent boost in productivity. These improvements not only lower costs but also ensure consistent product quality. With the right approach, you can transform your production process into a well-oiled machine.

Key Takeaways

- Prioritize the preparation phase by clearly understanding requirements, organizing your workspace, and planning workflows to eliminate bottlenecks.

- Implement real-time monitoring and data analytics during the execution phase to enhance efficiency and quickly address production issues.

- Adopt robust quality assurance practices, including regular evaluations and the use of advanced tools, to ensure high product standards and customer satisfaction.

- Embrace continuous improvement techniques like Kaizen to make incremental changes that enhance efficiency and quality over time.

- Avoid common pitfalls such as skipping the preparation phase and overlooking quality assurance to prevent costly errors and inefficiencies.

- Invest in advanced tools and training resources to equip your team with the skills needed for a successful production process.

- Focus on metrics like First Pass Yield and lead time to identify areas for improvement and optimize your production workflow.

Step 1: Preparation Phase in the Mainstream Production Process

The preparation phase lays the foundation for a smooth and efficient production process. By focusing on understanding requirements, setting up the workspace, and planning the workflow, you can eliminate potential bottlenecks and ensure a seamless transition to the execution phase.

Understanding the Requirements

Understanding the requirements is the first step in mastering the mainstream production process. You need to identify the specific goals and expectations for the production. This includes gathering detailed information about the product specifications, customer needs, and delivery timelines. Clear requirements help you avoid miscommunication and ensure that every team member works toward the same objectives.

To measure your readiness, consider tools like lead time analysis. Lead time tracks the duration from order placement to final delivery. It highlights inefficiencies and bottlenecks, allowing you to address them early. For example, if lead time reveals delays in material procurement, you can adjust your supply chain strategy to prevent disruptions.

Setting Up the Workspace

An organized workspace is essential for efficiency. Arrange tools, equipment, and materials in a way that minimizes unnecessary movement. A well-structured workspace reduces errors and saves time during production. For instance, placing frequently used tools within arm’s reach can significantly improve productivity.

Safety should also be a priority. Ensure that the workspace complies with safety standards to protect workers and maintain smooth operations. Proper lighting, ventilation, and ergonomic setups contribute to a safer and more comfortable environment. A safe workspace not only prevents accidents but also boosts morale and focus.

Planning the Workflow

Planning the workflow ensures that every step of the production process is clearly defined. Create a detailed roadmap that outlines tasks, timelines, and responsibilities. This roadmap helps you allocate resources effectively and avoid overlapping tasks. A well-planned workflow keeps the production process on track and minimizes downtime.

Incorporate quality control measures into your workflow. First Pass Yield (FPY) is a useful metric here. FPY calculates the percentage of products that pass quality inspections without needing rework. High FPY rates indicate effective quality control and streamlined processes. By integrating FPY into your workflow, you can identify areas for improvement and enhance overall efficiency.

“Lead time and First Pass Yield are critical metrics for identifying inefficiencies and improving production processes.”

By mastering the preparation phase, you set the stage for a successful mainstream production process. A clear understanding of requirements, an optimized workspace, and a well-planned workflow ensure that you are ready to move forward with confidence.

Step 2: Execution Phase in the Mainstream Production Process

The execution phase transforms your preparation into action. This is where production activities take place, and efficiency becomes critical. By focusing on core production tasks, following best practices, and ensuring safety compliance, you can achieve optimal results.

Core Production Activities

Core production activities form the backbone of the mainstream production process. These include assembling, manufacturing, or delivering the product or service. To maximize efficiency, you should adopt real-time monitoring systems. Manufacturers using real-time monitoring report up to 20% better efficiency compared to those who don’t. This approach allows you to identify and address issues immediately, reducing downtime and improving productivity.

Data analytics also plays a vital role in this stage. Factories leveraging manufacturing data analytics experience 30-50% fewer unexpected stoppages. This not only ensures smoother operations but also extends equipment longevity. By integrating these tools into your production activities, you can maintain a steady workflow and minimize disruptions.

Best Practices for Execution

Adopting best practices during execution ensures consistency and quality. Start by fostering efficient communication within your team. Clear communication helps address errors early, saving time and resources. Studies show that resolving issues early in the process is significantly cheaper and requires less effort.

You should also implement business process optimization strategies. Companies using these strategies save 10% or more on costs, avoiding billions in wasted time and money. Streamlining workflows and eliminating redundancies can lead to productivity gains of 30-50%. These improvements not only enhance output but also reduce operational expenses.

Additionally, consider incorporating AI into your production process. AI optimizes energy consumption, reduces labor costs, and minimizes waste. This creates a leaner, more cost-effective production environment, allowing you to focus on delivering high-quality results.

Maintaining Safety and Compliance

Safety and compliance are non-negotiable in the execution phase. A safe production environment protects workers and ensures uninterrupted operations. Begin by adhering to industry safety standards and conducting regular inspections. Proper safety measures reduce accidents and improve overall morale.

Quality management tools can further enhance safety and compliance. These tools help reduce error rates and prevent unnecessary costs due to rework or rejects. For example, ensuring compliance with safety protocols can avoid delays in delivery times, keeping your production schedule on track.

Incorporating these practices into your execution phase ensures a smooth and efficient mainstream production process. By focusing on core activities, following best practices, and maintaining safety, you can achieve consistent results and set the stage for quality assurance.

Step 3: Quality Assurance and Optimization in the Mainstream Production Process

The final step in mastering the mainstream production process focuses on ensuring the quality of your output and continuously improving it. This phase guarantees that your products meet the required standards and satisfy customer expectations. By evaluating the output, solving problems effectively, and embracing continuous improvement, you can maintain high-quality production and stay competitive.

Evaluating the Output

Evaluating the output is essential to identify whether the final product meets the desired standards. You should implement robust quality control methods to assess every aspect of the product. For example, industries like automotive manufacturing rely on detailed inspections to ensure safety and performance. These inspections verify that each component aligns with the specifications.

Advanced tools, such as manufacturing data analysis systems, can enhance your evaluation process. These tools convert production data into actionable insights, helping you detect inconsistencies or defects. For instance, AI-powered quality control systems use computer vision to identify flaws in real time. This technology minimizes errors and reduces the need for manual inspections.

“Toyota’s quality assurance principles emphasize a ‘customer first’ and ‘quality first’ approach, ensuring high standards for safety and reliability.”

By adopting similar principles, you can prioritize customer satisfaction and maintain consistent quality across your production line.

Troubleshooting and Problem-Solving

Even with thorough preparation and execution, issues may arise during production. Effective troubleshooting ensures that you address these problems promptly and minimize disruptions. Start by identifying the root cause of the issue. Use tools like Pareto analysis or fishbone diagrams to pinpoint the source of defects or inefficiencies.

Standardized processes play a crucial role in problem-solving. For example, a proper quality assurance system ensures that every team member understands their responsibilities and follows established guidelines. This consistency helps you resolve issues faster and prevents them from recurring.

AI and machine learning can also assist in troubleshooting. These technologies analyze patterns in production data to predict potential failures. By acting on these predictions, you can prevent costly downtime and maintain a smooth workflow.

Continuous Improvement

Continuous improvement is the cornerstone of long-term success in the mainstream production process. This approach involves regularly reviewing your processes and making incremental changes to enhance efficiency and quality. Techniques like Kaizen, which focuses on small, ongoing improvements, can help you achieve this goal.

Monitoring key performance indicators (KPIs) is vital for continuous improvement. Metrics such as defect rates, cycle times, and customer feedback provide valuable insights into your production process. Use these insights to identify areas for enhancement and implement targeted solutions.

Automation and AI further support continuous improvement. For example, AI-driven systems optimize workflows by analyzing production trends and suggesting adjustments. These advancements not only improve product quality but also reduce waste and operational costs.

“Continuous monitoring and improvement in quality assurance help optimize product development processes and deliver superior products.”

By embracing a culture of continuous improvement, you can adapt to changing market demands and maintain a competitive edge.

Common Mistakes to Avoid in the Mainstream Production Process

Skipping the Preparation Phase

Skipping the preparation phase often leads to inefficiencies and costly errors. When you neglect this critical step, you risk starting production without a clear understanding of requirements, an organized workspace, or a well-structured workflow. This oversight can result in delays, resource wastage, and subpar outcomes.

For example, Optikos faced challenges when delivering sub-assemblies in large quantities. The units failed during a higher assembly stage because of overlooked preparation details. By identifying failure modes and refining their processes, they improved manufacturing efficiency and reduced errors. This highlights the importance of thorough preparation in avoiding similar pitfalls.

To prevent this mistake, always allocate time to define goals, gather resources, and plan workflows. Use tools like lead time analysis to identify potential bottlenecks early. A well-prepared foundation ensures smoother execution and minimizes disruptions.

“Failing to prepare is preparing to fail.” This timeless principle applies directly to the production process.

Overlooking Quality Assurance

Overlooking quality assurance compromises the integrity of your final product. Without proper evaluation, defects can go unnoticed, leading to customer dissatisfaction and potential financial losses. Quality assurance is not just a final checkpoint; it is an ongoing process that ensures consistency and reliability.

Consider industries like automotive manufacturing, where rigorous inspections are non-negotiable. Skipping these steps could result in safety hazards or recalls. Similarly, in your production process, neglecting quality checks can lead to rework, wasted materials, and missed deadlines.

To avoid this mistake, implement robust quality control measures at every stage. Use tools like First Pass Yield (FPY) to monitor the percentage of defect-free products. Advanced technologies, such as AI-powered inspection systems, can further enhance accuracy and efficiency. These systems detect flaws in real time, reducing the need for manual intervention.

“Quality is never an accident; it is always the result of intelligent effort.” Adopting this mindset ensures that your production process consistently delivers high standards.

By addressing these common mistakes, you can strengthen your production process and achieve better results. Prioritize preparation and quality assurance to build a reliable and efficient workflow.

Tools and Resources for Success in the Mainstream Production Process

Mastering the mainstream production process requires the right tools and resources. These elements not only enhance efficiency but also ensure consistent quality. By leveraging advanced equipment and investing in learning opportunities, you can optimize your production workflow and stay ahead in a competitive market.

Recommended Tools and Equipment

The right tools and equipment form the backbone of an efficient production process. Advanced manufacturing systems, such as the Mainstream MRAM System, offer cutting-edge capabilities. This system uses a six-Degree-of-Freedom (DoF) robotic arm, enabling multi-axis movements and material deposition on curved surfaces. Its versatility allows you to integrate tools like extruders, pick-and-place devices, and milling spindles, making it ideal for complex production tasks.

For industries like aerospace, additive manufacturing (AM) tools have revolutionized production. AM methods create fixtures, jigs, and gauges with remarkable precision. These tools reduce production time and improve accuracy, ensuring compliance with strict safety standards. Incorporating such technologies into your workflow can streamline operations and minimize errors.

Data-driven tools also play a crucial role. Manufacturing Data Analytics systems help you monitor performance, reduce downtime, and eliminate waste. These tools provide actionable insights, enabling you to maintain consistent product quality. Real-time monitoring systems further enhance efficiency by identifying issues before they escalate, ensuring smooth operations.

“Investing in advanced tools not only improves efficiency but also ensures that your production process meets modern standards.”

Learning and Development Resources

Continuous learning is essential for staying competitive in the ever-evolving manufacturing landscape. Training programs focused on Quality Control Methods equip your team with the skills needed to identify and address defects. These programs foster a culture of excellence, ensuring that every product meets customer expectations.

Online courses and certifications in Quality Assurance vs. Quality Control provide valuable knowledge about maintaining high standards. These resources help you understand the nuances of quality management, enabling you to implement effective strategies in your production process.

Workshops and seminars on In-Process Testing in Production offer hands-on experience with performance measurement techniques. These sessions teach you how to evaluate sub-assemblies and finished products, ensuring that your output aligns with industry standards. By mastering these skills, you can prevent costly rework and maintain customer satisfaction.

Additionally, investing in leadership development programs enhances team coordination. Strong leadership ensures that every team member understands their role, contributing to a cohesive and efficient production process.

“Knowledge is the foundation of success. Equip yourself and your team with the right resources to excel in the mainstream production process.”

By combining advanced tools with robust learning resources, you can achieve excellence in the mainstream production process. These investments not only improve efficiency but also ensure that your products consistently meet the highest standards.

Benefits of Mastering the Mainstream Production Process

Increased Efficiency

Mastering the mainstream production process significantly boosts efficiency. By optimizing workflows and eliminating unnecessary steps, you can save time and resources. For instance, companies that adopt business process optimization strategies often achieve cost savings of 10% or more. Streamlined processes reduce delays, allowing you to meet deadlines consistently.

Data analytics plays a crucial role in improving efficiency. Plants that implement manufacturing data analytics report material waste reductions of 15-25%. This not only minimizes costs but also ensures better resource utilization. Additionally, statistical analysis helps refine process parameters, reducing cycle times and increasing throughput. These improvements create a smoother production flow, enabling you to handle higher volumes without compromising quality.

“Efficiency is doing things right; effectiveness is doing the right things.” – Peter Drucker

By focusing on efficiency, you can enhance productivity and maintain a competitive edge in your industry.

Enhanced Product Quality

A well-mastered production process directly impacts product quality. When you prioritize quality assurance and optimization, you ensure that every product meets high standards. This consistency builds trust with customers and strengthens your brand reputation.

Advanced tools like manufacturing data analysis systems help identify defects early. These systems convert production data into actionable insights, allowing you to address issues before they escalate. For example, statistical insights can optimize process parameters, ensuring uniformity in product output. Even a small boost in efficiency can lead to noticeable improvements in quality.

“Quality is not an act; it is a habit.” – Aristotle

Continuous improvement further enhances product quality. Techniques like Kaizen encourage small, ongoing changes that refine your processes over time. By embracing this mindset, you can adapt to evolving customer needs and maintain superior standards.

Mastering the mainstream production process ensures that your products consistently exceed expectations. High-quality output not only satisfies customers but also reduces rework and waste, saving you time and money.

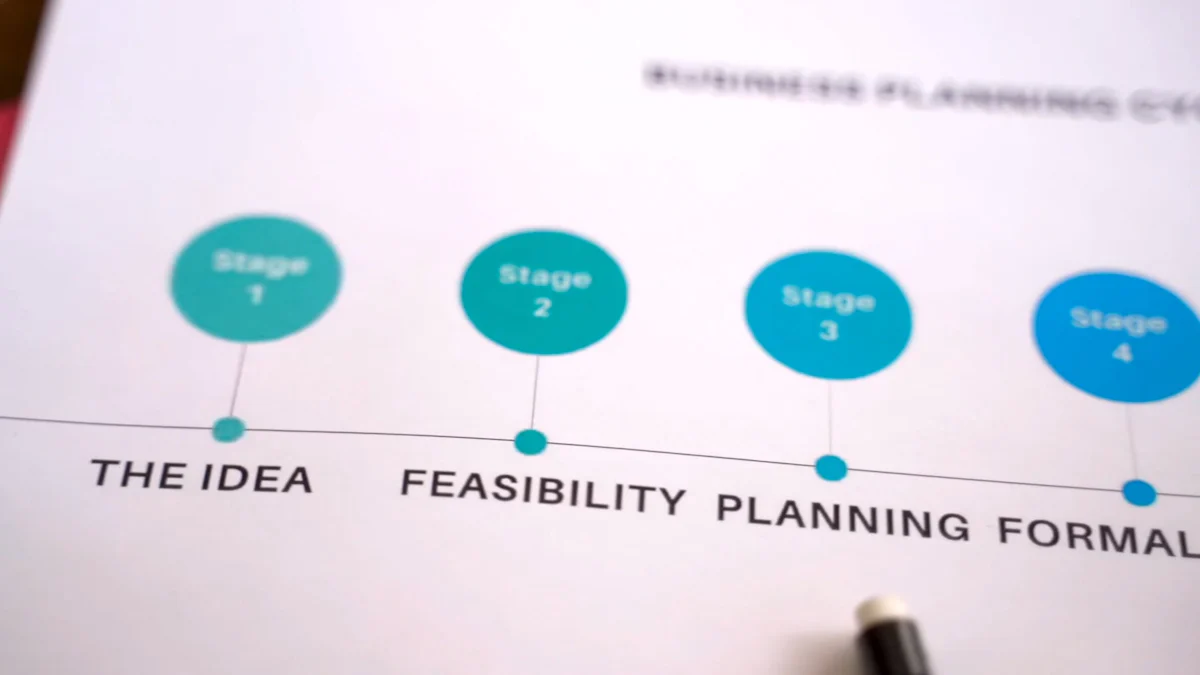

Mastering the mainstream production process involves three essential steps: Preparation Phase, Execution Phase, and Quality Assurance and Optimization. Each step builds on the other to create a seamless and efficient workflow. By focusing on these areas, you can improve productivity, reduce waste, and enhance product quality.

Continuous learning and improvement remain crucial. Tracking metrics like yield rate helps you identify inefficiencies and refine your processes. Even small adjustments can lead to significant gains in efficiency and quality.

Apply these steps in your production process. Share your experiences and insights to inspire further growth and innovation.

See Also

Comparing Variations Among Popular ST-4ETD202 Model Products

Investigating TMS320F28335PGFA For Real-Time Control Applications

Achieving Signal Control Mastery Using AD9850BRSZ-REEL Innovations

Leveraging Data-Driven Automation Through PIC16F1824-i/SL Microchip